When Pressure Falls, Wax Can Fade

Wax Leaning in Gas Condensate Fields: Reducing Overdesign

TLDR

In many gas-condensate systems, as reservoir pressure is depleted, the heaviest, wax-forming components are increasingly left behind in the reservoir. The produced stream “leans out” and becomes lighter, less waxy, with fewer production headaches. This isn’t magic; it’s phase behaviour + porous-media physics. Below, we unpack what reservoir leaning is, what strengthens it, and how to operate to capture the advantages it offers.

Wax remains a big flow assurance risk in hydrocarbon production, as we have written about in many previous case studies.

While those were predominantly oil systems, wax related risks in gas-dominated systems present their own unique set of challenges:

Sampling gaps: Pre-production sampling can fail to capture and/or quantify accurately the heavy paraffinic components

Model limits: The tools may be insufficient to accurately predict the wax deposition in gas-dominated systems as they are largely based on single-phase, laminar flow, with 0% water oil-dominated systems

Hydrate focus: As gas-dominated systems are usually governed by hydrate requirements (i.e. continuous MEG/MeOH injection), the passive insulation requirements are removed which eventually leaves the system to cool faster leaving more potential for wax related risks

Chemical conflicts: Paraffin inhibitors may be incompatible with other chemicals (i.e. MEG) and/or be difficult to deploy due to high viscosity

Changing fluids: Reservoir pressure decline can shift fluid composition over life-of-field, changing risk profile (i.e. severity, location, treatment options, etc.)

While wax content in condensates is typically lower than in oil fields - and may have a different hydrocarbon distribution - it can still reach levels high enough to create serious flow restrictions with time, especially in specific reservoirs or under certain operating conditions. We’ve seen more than a few gas-condensate fields where wax became a real operational challenge—one that had to be anticipated and mitigated well before production started (and was often not…).

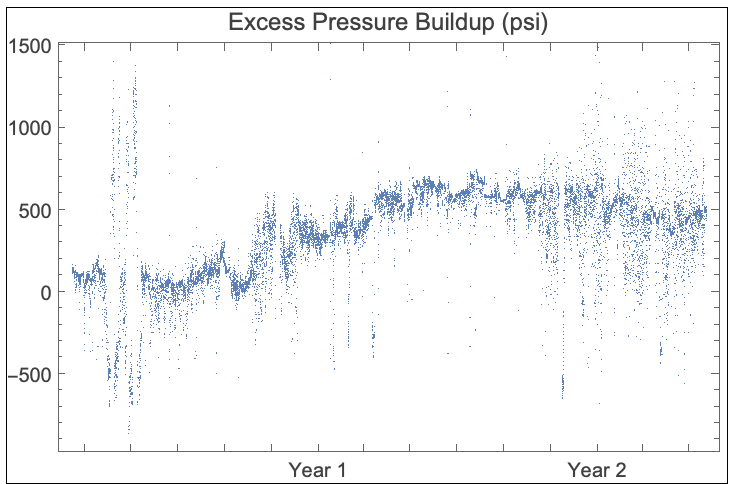

The fact is - we should worry about wax issues at the design stage, because there is not an “easy” and straight-forward answer for dealing with paraffin-related issues in gas systems when they arise. Example below with an excess dP observed in early field life which is proofed to be from a wax presence, which was not anticipated prior to start-up.

The negative consequences of unexpected wax are numerous:

Higher back-pressures, leading to deferred production and/or accelerated well phasing.

Inability to remediate (i.e. stuck pig) should a remediation campaign be required.

Inability to spot chemical treatment if sufficient access points are not provided in the system design

Potential integrity management concerns (i.e. under-deposit corrosion), particularly in the event of solids production.

As awareness grows, operators can pull these concerns forward and cater for them in the design…at a cost! Designing for continuous wax-inhibitor injection or insulating a system to stay above the Wax Appearance Temperature (WAT) can drive costs so high that smaller gas-condensate developments struggle to stay economic.

And there we come into the game…. Diving deeper into the life cycle of the field and unlocking the potential.

Life of a Gas Condensate in the Reservoir

For those who think that gas condensate fluids contain little or no wax, let’s break that down:

“Little” wax? Fair - but even small amounts can precipitate and deposit, and those deposits can build up over time. And, given the nature of gas fields - which typically are allowed to produce at colder temperatures (due to continuous hydrate chemical program), larger amounts of wax can precipitate as dictated by the wax precipitation curves (more on that below…)

“No” wax? Extremely rare. And be careful: if you’re basing that claim on topsides samples, you may be misled.

Wax content should be assessed from bottomhole samples to capture the heavy ends before they drop out.

Topsides fluids often arrive at temperatures below the Wax Appearance Temperature (WAT), so the heavier components may have already precipitated or deposited along the wellbore, leaving you with an artificially “clean” sample.

The ultimate challenge remains: To Design or Not Design for Wax?

Under-design can lead to lost production and costly remediation

Over-design can lead to uneconomic project

When developing a new system, using accurate measurements is critical—but we also have to remember how a reservoir changes over time. Most gas-condensate reservoirs undergo natural depletion, meaning pressure falls steadily while temperature stays essentially constant.

The phase envelope below illustrates the point: as production continues, the reservoir pressure can drop dramatically, even while temperature remains unchanged. Eventually, the pressure will fall below the dew-point curve, and condensate will begin to drop out inside the reservoir itself, before it reaches the wellbore.

Why does that matter? Because as the reservoir depletes:

The produced condensate-gas ratio (CGR) declines.

More of the heavy ends (including n-paraffins) remain in the reservoir.

This phenomenon is also known as ‘condensate banking’, which is good from a wax risk perspective, but on the other side is bad from a well productivity perspective as the dP near the wellbore may increase over time.

However, every gas-condensate field must be evaluated case-by-case. Each reservoir’s phase behaviour is unique, and the “benefit” of pressure depletion, where lower CGR might reduce heavy ends reaching surface facilities, can vary widely:

In some reservoirs, the CGR decline is modest, so any reduction in wax risk is minimal.

In others, especially wet-gas systems (see below example) where the reservoir temperature lies to the right of the cricondentherm, which means that condensates and heavy ends will never drop out in the reservoir.

This variability underscores why wax-risk assessments for gas-condensate developments can’t rely on generic rules of thumb. Rule of thumb will work, but can make the development overdesigned and uneconomical. Detailed fluids analysis and reservoir wax leaning should be taken into consideration for a more optimum field development.

Wax “Leaving the Chat”

As always, let’s ground the discussion with a real case study.

We recently worked on a gas field with potentially waxy condensate. The fluids were fully characterized with a measured n-paraffin distribution and tuned to a measured Wax Appearance Temperature (WAT), which were deemed accurate for the collected samples. Taking everything into consideration, the following data were included for the reservoir wax leaning estimation:

Fluid compositions, HTGC and WAT of every sample

Reservoir pressure depletion over time

Production forecast over time

Worth noting that the fluid leaning done confirmed subsurface estimates on expected condensate yield (decline) over time. It was a satisfying cross-check that confirmed our methodology. But raises the question - if forecasts are showing declining condensate (which we take credit for) due to changing composition, shouldn’t our paraffin risk also change over time?

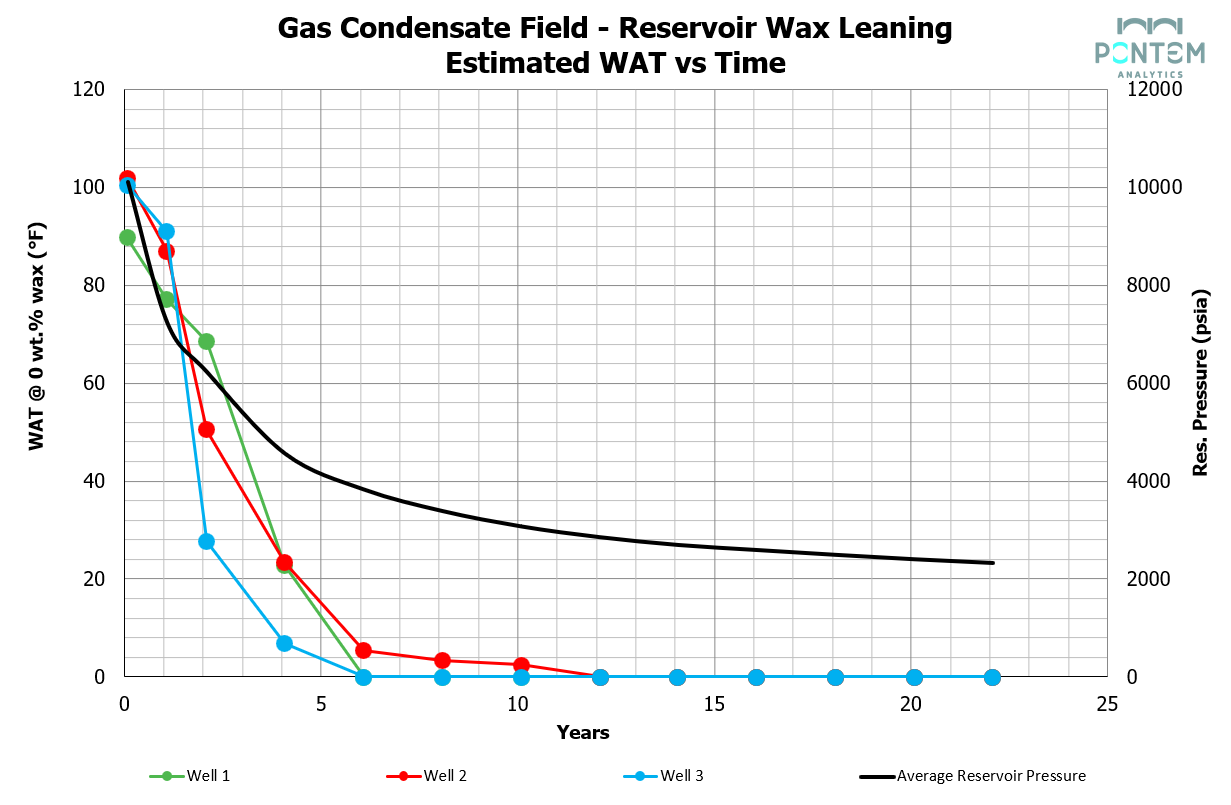

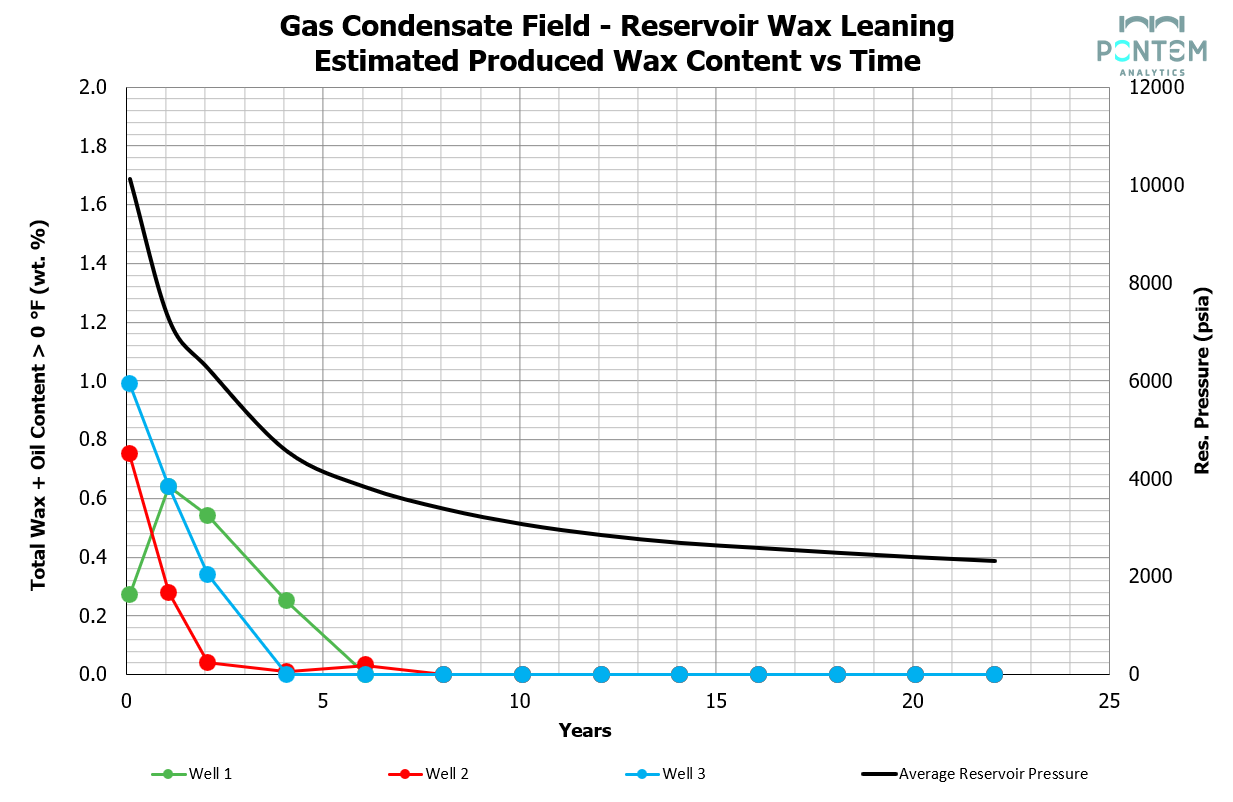

To understand the wax risk of the system over time, some important wax parameters were evaluated. Anyone familiar with wax modelling will recognize the key parameters we focused on:

WAT (Wax Appearance Temperature) – The temperature at which wax crystals first begin to precipitate from the fluid under a given pressure.

Wax Content – The total mass fraction of paraffinic hydrocarbons present in the fluid that can precipitate as solid wax. Another way of illustrating this is the WPC (Wax Precipitation Curves), but we will keep it easy by only presenting the total wax that can precipitate.

Below are each of the above parameters along reservoir pressure depletion for some of the wells just to capture and illustrate the overall behaviour:

WAT (Wax Appearance Temperature)

What we see immediately (given a ~40°F seafloor temperature for this deepwater development), is the WAT reduces below ambient by Year ~3.5. Or, alternatively, when the reservoir pressure depletes below ~4000 psi, we are expected to be producing ‘wax-free fluids’.

Wax Content (n-C20+)

The plots tells a similar story: wax content is dropping over time (with declining reservoir pressure) which leads to a lower wax risk vs. time. Again, depending on actual reservoir pressure decline, by Year ~3 most wells are producing fluids with WAT below ambient temperature, effectively meaning wax risk has already “left the chat.”

Now consider the implications for modelling:

Year-0 characterization only: If we had modelled wax deposition over the entire field life using just the initial fluid properties, the predictions would have overstated the risk.

Wax modelling considering reservoir wax leaning: Incorporating the observed wax-leaning behaviour paints a more accurate picture of how deposition changes through time.

For this field, some wax deposition is expected during the early years of production, but the overall volume is expected to quickly dissipate. This time-dependent understanding enables significant optimization:

Lower wax-inhibitor injection rates, adjusted downward as the fluid naturally becomes leaner in wax.

Reduced pigging frequency, since long-term deposition is not critical.

It is really this last point - pigging assessment - that deserves attention and focus. Routine pigging for wax management, particularly for subsea tiebacks, is costly (downtime), risky (stuck pick), and logistically challenging (subsea launchers vs. dual flowlines, etc.). Building permanent pigging capabilities based on the assumption of routine pigging throughout field life may be required. However, knowing that wax risk reduces over time - and potentially a ‘wax-in-place’ strategy may be feasible - potentially makes a significant improvement to overall project economics. Adding upfront CAPEX that may not be required a few years into production is a decision that should be factored into upfront project design.

Conclusions/Takeaways

By updating the model with real-time data and wax-leaning trends, including continuous monitoring, operators can maintain flow assurance while cutting chemical and maintenance costs, avoid overdesigning the field and optimizing operation which eventually unlocks the potential of the fields that earlier were deemed economically not-feasible.

Over time, natural wax-leaning can reduce the amount of wax available to deposit and lower the WAT. By incorporating these time-dependent changes into modelling, rather than relying on a single year-0 characterization, operators can:

Avoid over-designing mitigation measures

Optimize wax-inhibitor injection rates

Reduce pigging frequency

Improve overall project economics

In short, careful characterization and continuous updating of wax-deposition models transform a perceived high-cost challenge into a manageable and economically efficient strategy for gas-condensate developments.