Untapped Potential: Seafloor Hydrates

Gas Extraction from Seafloor Methane Hydrates

Working in upstream gas production, Pontem spends a huge amount of time and energy on mitigating the formation of methane hydrate formation within production systems to ensure safe and reliable flow, but recently we have begun exploring the potential of unlocking the value in naturally occurring methane gas hydrate deposits located offshore Japan. This presents a formidable engineering challenge, but the potential rewards in terms of regional energy security are substantial and have driven a wave of research and development. Read on to hear about how Pontem have been working to tackle these engineering challenges.1

What is the Market for this Technology?

Japan is a relatively small island nation with a large population and a booming industrial sector. The population and heavy industries demand a large amount of energy to prosper, and relies heavily on costly LNG imports from Australia and Qatar to fulfill these requirements. This leaves the nation at the mercy of fluctuating price markets and erratic government policies aimed at depriving gas operators of the ability to export this vital cargo. As a hub for innovation and technological advancement, Japan has turned its focus locally to define its own path toward energy security.2

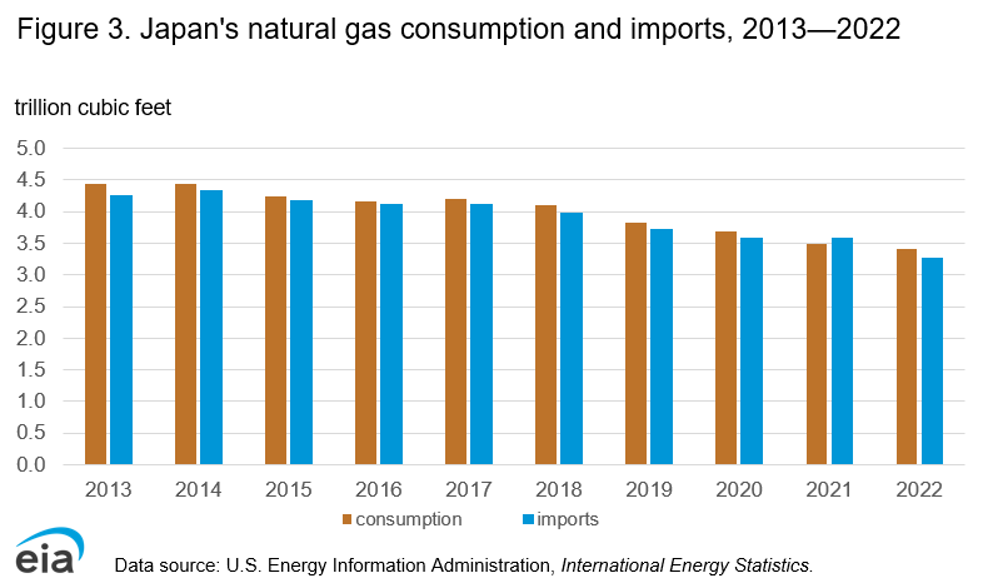

In 2022, Japan consumed approximately 3.5 trillion cubic feet of gas and are predicted to continue around this level until 2050. Approximately 50 km offshore Japan in the Nankai Trough sits 1.1 Trillion cubic meters (~39 trillion cubic feet) of natural gas methane deposits3. Therefore, there is approximately 10 years worth of vital energy for the Japanese people available… if they can break through the technical challenges we will discuss below. Obviously extracting all of this deposit is not a realistic outcome, however it does give a scale to the potential size of the prize available for the Japanese people.4

What are Naturally Occurring Methane Hydrate Deposits?

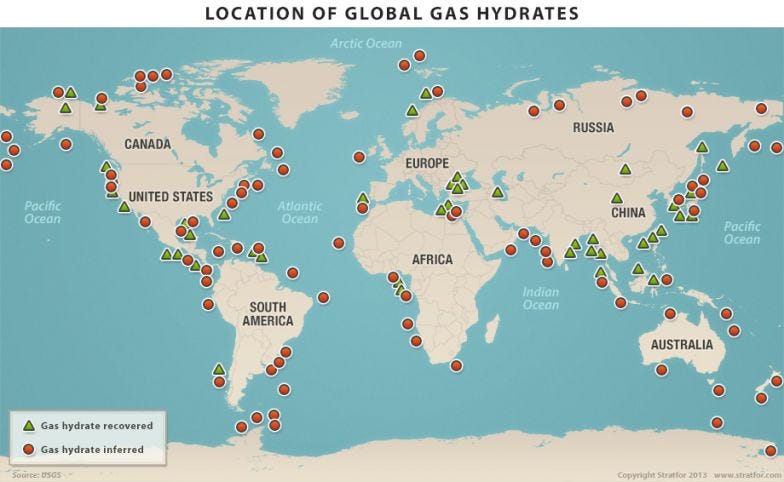

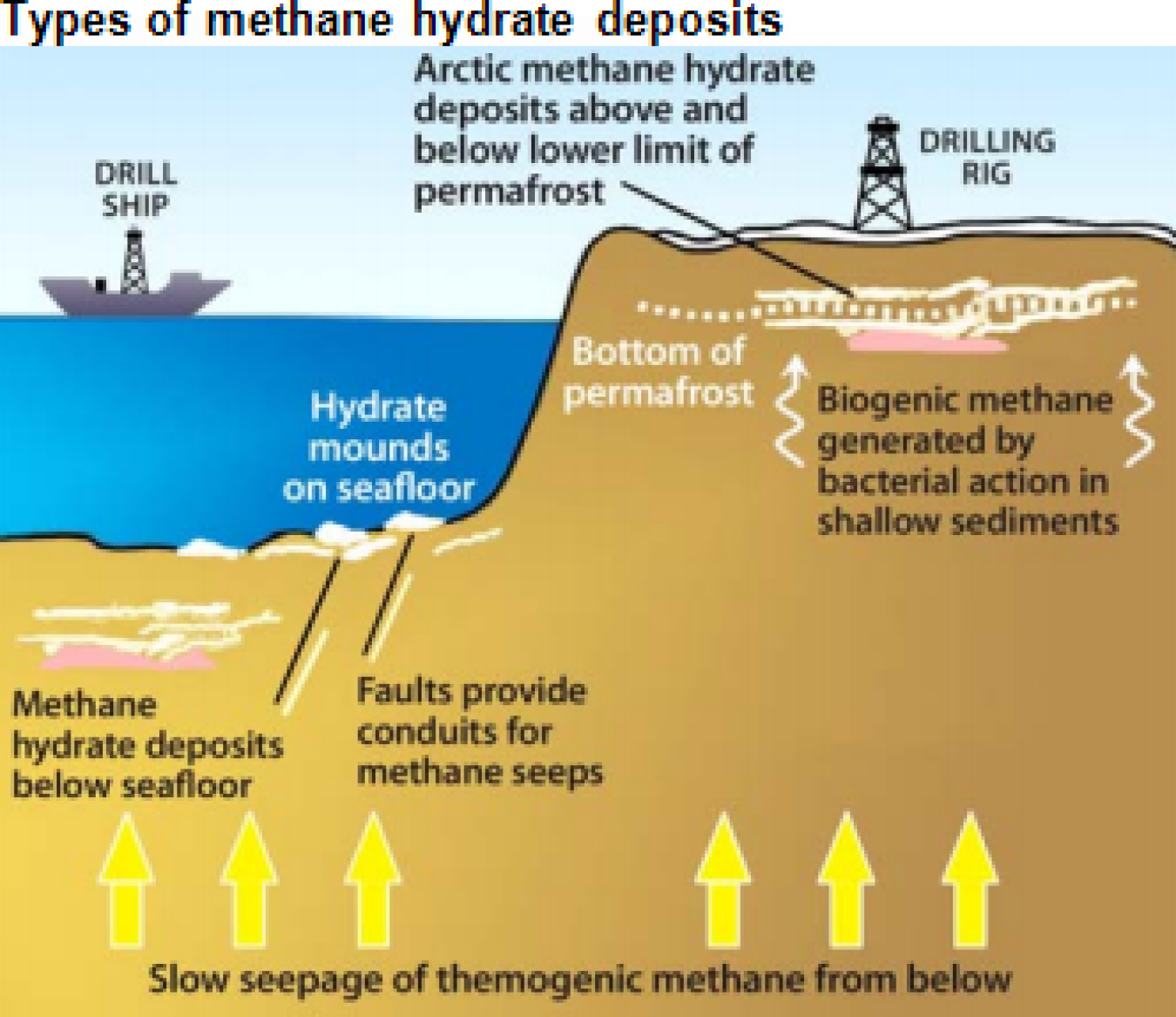

The formation of methane hydrate deposits is not just a phenomenon that occur in the production of oil and gas, they occur naturally all over the globe in the right conditions. Methane gas hydrates are crystalline solids in which methane molecules are trapped within a lattice of water at elevated pressures and reduced temperature conditions. In nature, gas can evolve from subsurface deposits and bubbles to the surface. In cold, high-pressure regions—such as permafrost zones or deep ocean sediments—the escaping gas can gas can form a solid hydrate just below, or even on, the seabed.

Turning an Idea into Energy

There are three primary methods of disassociating a methane hydrate back into its core components; methane and water:

Pressure: Reducing the pressure to below the hydrate equilibrium pressure.

Temperature: Increasing the temperature to above hydrate equilibrium temperature.

Thermodynamic Hydrate Inhibitor (THI): The direct application of THI to shift the hydrate equilibrium conditions outside of in-situ conditions.

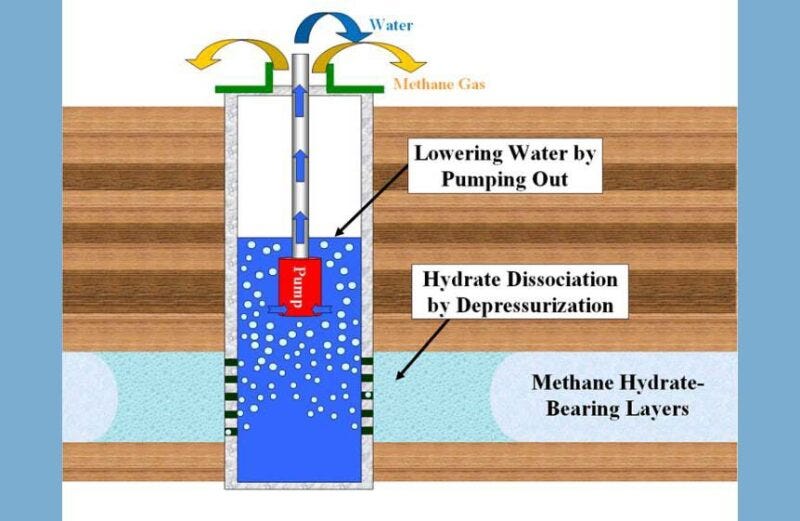

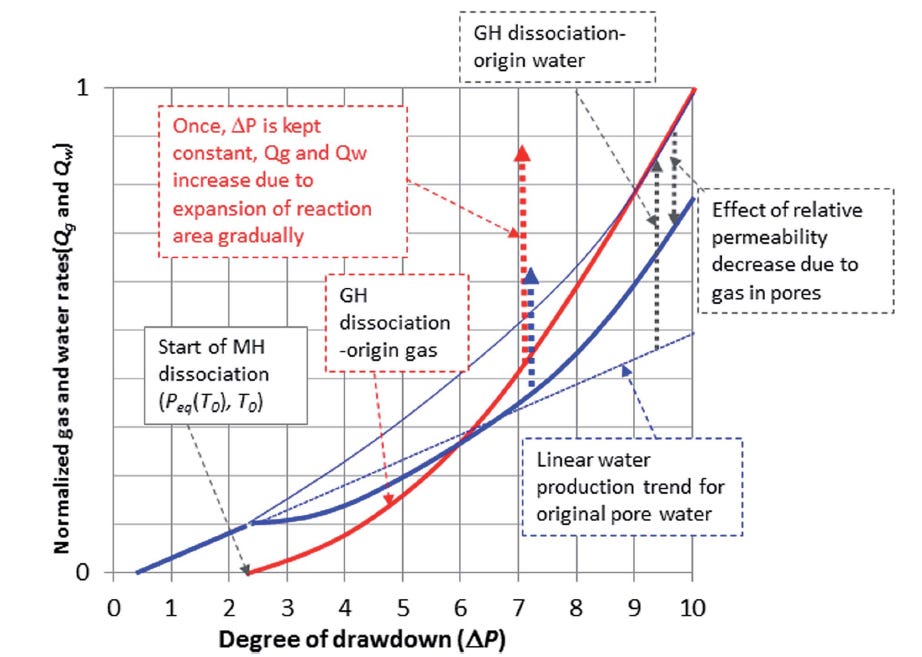

Due to the large size of the hydrate deposits, applying the whole area with expensive THI or trying to heat such a wide area is not practical. Therefore, the primary method of disassociating the hydrate and releasing the trapped methane is to reduce the overburden of pressure on the deposit. This is achieved by drilling into the deposit and using an Electrical Submersible Pump (ESP) to unload the water column exposing the formation to pressures below hydrate equilibrium pressures.5

Once the methane and water have reached the surface, the two components are processed through a separator to obtain the gas and dispose of the water. While the concept is straightforward in theory, the practical implementation presents significant challenges. The concept works and has been field tested, but not without some challenges:

Hydrates (again): Much like in the remediation of a conventional hydrate blockage in a subsea component, once the deposit is remediated it has a propensity to reform and block the flow path back to the separator. As the remediated gas is dissolved it can cool along the tubing string due to thermal losses to the surroundings and expansion (JT) cooling along the flow path.

Slugging: The molar ratio of water to methane in a hydrate structure is 5.75:1, not accounting for incomplete cage filling in the hydrate structure. This is a significantly higher amount of water, especially when accounting for the incompressibility of the liquid phase. Slugging entering the ESP causes instability and potentially gas lock which can cause the ESP to fail.

Sand: Due to instability in the fragile hydrate formations, the production of water and gas comes with a significant quantity of solid sand particles. The sand particles cause erosion and wear on the well components and can result in an ESP failure.

Reservoir Performance: As the hydrate formation is depleted, the size and structure of the solid hydrate structure changes dynamically. The consistently varying conditions of the hydrate formation as it dissociates makes the prediction of reservoir performance challenging to predict.

Further to the above technical challenges, the production of naturally occurring methane hydrate deposits comes with the associated economic challenges. The gas production flow rates from these wells are typically low compared to conventional gas reservoirs and thus many wells are required to deliver a rate which could be considered economical.

Unpredictable Prediction

Addressing the technical flow assurance challenges associated with gas hydrate production requires detailed multiphase modelling. Accurate prediction of the slugging behavior will dictate ESP selection and additional equipment requirements, such as gas-handling units. Furthermore, the thermodynamics of the system require rigorous thermodynamic models to ensure hydrate reformation does not occur along the flow path and kill the production.

Pontem applied its modelling expertise to create detailed multiphase model of the system in OLGA using downhole ESPs, gas-liquid handling, complex thermodynamic models and slug tracking to capture the thermo-hydraulic behavior as accurately as possible. Recently published data in the Journal article The Second Offshore Production of Methane Hydrate in the Nankai Trough and Gas Production Behavior from a Heterogeneous Methane Hydrate Reservoir6 allowed Pontem to benchmark the transient well behavior to ensure that modelling outcomes would be as representative as possible of actual field conditions.

The development of an accurate fluid model, combined with laboratory testing and vendor engagement, allows operators to enter the next phase of well testing with more confidence in well design and technology selection, driving the next steps towards a commercially viable development.

The Future

Currently, the exploration of natural gas hydrate formation production is in the pilot phase to attempt to uncover the optimal production methods to deliver this resource. Due to the technical and economic challenges discussed above, the production of naturally occurring methane hydrate deposits is not commercially viable at this time. Nonetheless, multiple extended well tests have already been conducted in Japan, China, and the United States.

In October 20237, the Japanese Organization for Metals & Energy Security (JOGMEC) began a successful long-term production test at Purdue Bay on Alaska’s North Slope. Unlike previous tests, this operation was performed on permafrost hydrate formations located onshore, reducing the technical challenges and providing hope for a new frontier of gas production in the region.

It remains to be seen whether the production of naturally occurring methane gas deposits becomes a long term commercial energy source. However, Pontem is proud to have supported this technology and are excited to see what the future holds in this area.

https://worldview.stratfor.com/article/methane-hydrates-new-energy-windfall

https://www.afr.com/companies/energy/pm-insists-there-s-no-rush-on-major-gas-call-due-on-may-31-20250514-p5lz6p

https://www.bbc.com/news/business-21752441

https://www.eia.gov/international/analysis/country/jpn

https://jpt.spe.org/twa/completion-design-strategy-production-testing-gas-hydrate

Yamamoto, K., Wang, X., Tamaki, M., Suzuki, K., The second offshore production of methane hydrate in the Nankai Trough and gas production behavior from a heterogeneous methane hydrate reservoir, RSC Adv., 2019, 9., 25987.

https://www.upstreamonline.com/production/methane-hydrates-on-long-term-production-in-alaska/2-1-1581124