A Decade of Flow: How OLGA Has Evolved to Support Gas Condensate Systems

Looking at OLGA performance and improvements from 2015 to 2025 for gas condensate systems

TLDR - Two key takeaways from this post:

1 —> Latest is NOT always the greatest.

2 —> All models need to be benchmarked and validated.

Background

One of the core responsibilities in flow assurance and production engineering is the ability to accurately model field behaviour, whether it’s a brownfield or greenfield development. These models help predict and prevent issues like slugging, hydrate formation, wax deposition, and excessive pressure drops, while also supporting system design (pipelines, separators, pumps) and troubleshooting by recreating real operating conditions. In essence, we aim to replicate physical reality in a controlled environment to enable informed, proactive decisions throughout a field’s lifecycle.

Most oil and gas fields today involve multiphase flow, a mix of oil, gas, water, and occasionally solids. Accurately simulating this requires robust transient flow simulators, with OLGA (developed by Schlumberger, originally by SINTEF and IFE) widely regarded as the industry standard.

OLGA’s strength lies in its decades of development and validation, making it a trusted tool for design and operational studies. While competitors like LedaFlow and in-house simulators offer niche advantages, OLGA’s first-mover status, reliability, and wide adoption keep it at the forefront of the industry.

Regardless of how advanced or well-validated a simulator is, achieving a perfect match between model predictions and field behavior rarely happens on the first try. This mismatch can stem from a wide variety of factors, not all of which are related to the simulator itself. Some of the most common causes include:

Uncertainties in the produced fluid

Changes in actual field conditions

Assumptions made during model setup

Instrument calibration or data integrity issues

Simplifications of system geometry or topology

Forecast inaccuracies

and of course human errors

These challenges highlight an important point, that most of the people are missing:

Modeling is a continuous process, not a one-time task. It involves iterative benchmarking, continuous validation and updates when new data is available.

Like all software, OLGA has gone through regular updates over the years. These updates are driven by feedback from operators, academia, and lab validation studies. As we touched on briefly in our previous post on this topic (link below), staying up to date with the latest version of OLGA, and understanding the implications of each update, is crucial for maintaining modelling accuracy and reliability. In this article, we’ll discuss a little more closely some of those updates and finally how we have seen their impacts play out in real-world examples.

Flowing Uphill in Tanzania

Jambo! Mambo? Poa…Poa Kuku! (When you spend a few weeks in Tanzania, you pick up a little Swahili along the way). This trip will take us from -2500m below sea level to +6000m above sea level, a distance nearly as tall as Mt. Everest. But, in Africa, there really is only one big mountain of interest….

A decade of flow: How OLGA has evolved

As mentioned in the introduction, continuous software development is essential to improving the accuracy and reliability of flow simulations. OLGA, has consistently delivered annual updates, enhancing core functionality, adding new features, and fixing critical bugs.

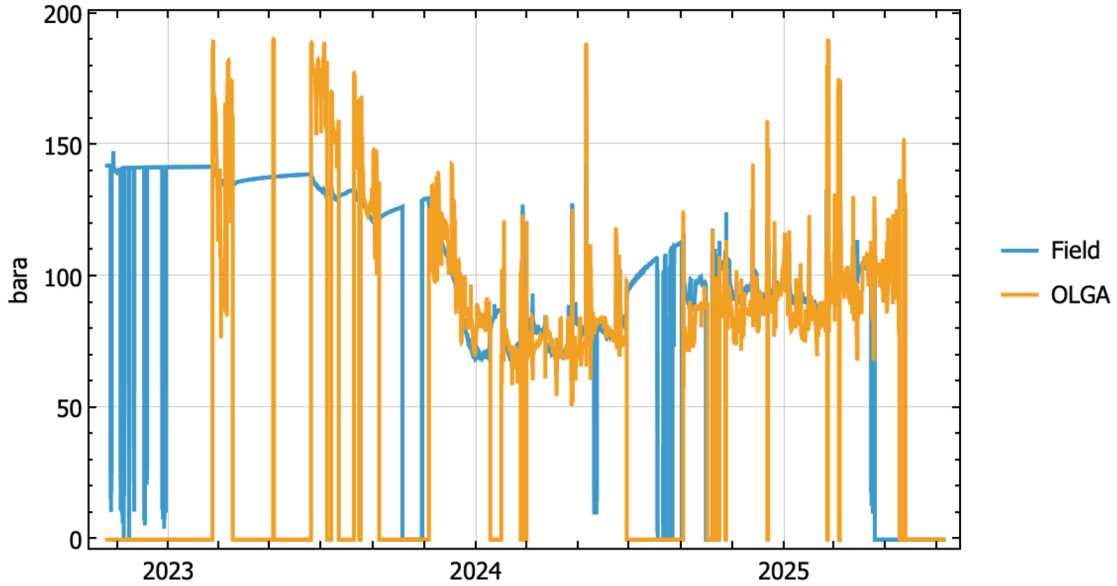

From practical experience and benchmarking studies, we’ve observed that OLGA generally performs very well in single-phase and oil-dominated systems (separate post to follow focused on oil dominated systems). As an example, you can see the inlet pressure comparison between the oil field and OLGA simulations (over last 2 years) from work we did just last week…

However, its performance becomes more variable in gas condensate systems and low turndown production scenarios, some of the most complicated scenarios for multiphase fluid dynamics.

Over the past decade, specific updates have aimed to address these limitations, advancing OLGA’s ability to replicate complex field phenomena and reducing the need for excessive manual tuning. The following is a curated summary of key model-relevant updates made between OLGA 2015 and OLGA 2025.

2016–2019 and 2021-2024: “Steady progress”

During these years, OLGA saw a number of incremental fixes and technical enhancements. However, from a model benchmarking and field matching perspective, none of the changes were groundbreaking. They included general improvements in numerical stability, convergence speed, GUI usability, and bug fixes related to specific edge cases, but these had limited direct impact on core flow predictions specifically for benchmarking.

2020 OLGA Update: “Major improvements”

The 2020 release marked a significant turning point, especially for challenging applications like gas condensate flow systems and pigging simulations. Several updates stood out for their direct impact on matching field data more accurately:

1. New Apparent Liquid Film Wall Roughness Model

This update was particularly impactful for pressure drop prediction in low-liquid loading flows, a well-known challenge in gas condensate pipelines. Previously, OLGA tended to underpredict pressure drops at high gas rates in gas condensate systems. To compensate, users often manually increased pipe wall roughness, an artificial fix that lacked physical basis.

With OLGA 2020, a more physics-based approach was introduced:

The HD stratified flow model was updated to include a new closure for the effective film roughness generated by the thin liquid film creeping up the pipe wall at high gas velocities which was validated against extensive experimental data from SINTEF and IFE laboratories, showing far better agreement for pressure drop prediction in gas-condensate systems.

For the technical audience, the equations added for the effective film roughness look like follows (contact us if you want to know what each variable is, and how they work)The mechanism now considers turbulence-driven film spreading as a function of gas rate and film viscosity.

2. Enhanced Pigging Model

The pig model saw also major refinements:

Enhanced pigging physics: Improved handling of holdup fronts, fluid segregation, flash behavior, and leakage scenarios.

Greater numerical stability: More robust simulations under transient conditions, with better physical realism.

3. Slug Initiation and Liquid Accumulation Enhancements

Introduction of a new slug initiation model, improving the prediction of slug formation in stratified and transition flow regimes.

Better modelling of water accumulation at low flow rates and gravity-dominated flow, common conditions in long, horizontal flowlines with liquid dropout risk.

2025 OLGA Update: “Further refinement”

The 2025 release introduced targeted improvements that continue the work begun in 2020, further improving simulation of stratified and dispersed flows in multiphase systems:

1. Advanced Closures for HD Stratified Flow Model

New closures were implemented for turbulence parameters, capturing the apparent eddy viscosity at the gas-liquid and liquid-liquid interfaces. OLGA keeps the actual expressions used proprietary (apologies for the curious people!)

This helps simulate the momentum exchange across interfaces more accurately, especially in complex gas condensate environments where stratified layers and internal mixing strongly affect dP and phase separation.

2. MEAN Slug Tracking Model

A new statistical slug tracking mode was introduced.

Over the past decade, OLGA has taken major steps forward in improving simulation accuracy for challenging systems, particularly gas condensate and low liquid loading environments. The updates in 2020 and 2025 represent key milestones in reducing the mismatch between modelled and actual field behaviour, and in minimizing the need for arbitrary tuning.

Enough of theory…. Let’s go ahead and have a look on how OLGA compares to the field throughout the years and how that compares to the required tuning/benchmarking.

Model vs. Reality: What have we seen at Pontem?

With some of the history and theory behind us, let’s look at how these updates have actually played out in terms of matching field data through a few examples.

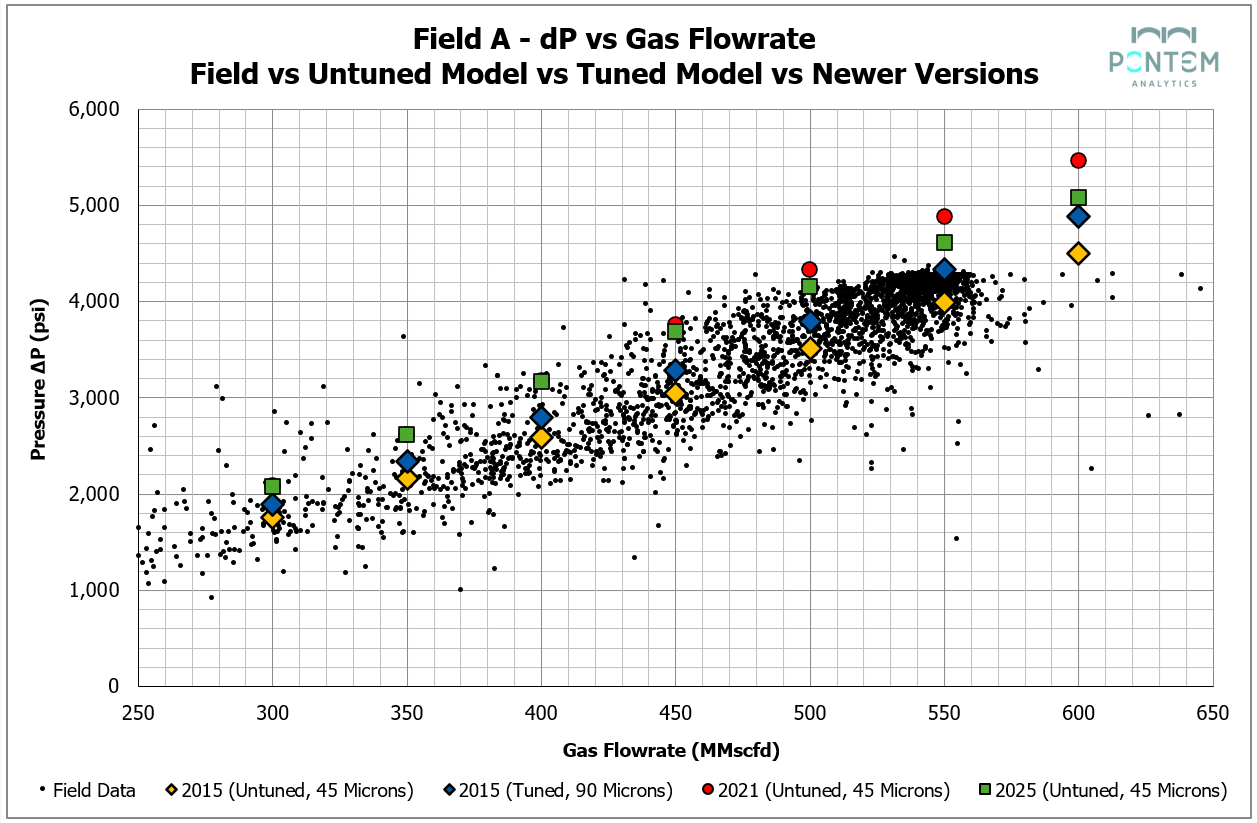

“Field A”: Subsea-to-platform tieback in a deepwater basin

This field involves a deepwater subsea development producing a lean gas-condensate fluid, with long multiphase transport lines connecting subsea wells to a fixed platform. The system is known for low liquid loading and stratified flow regimes, particularly under turndown or early-life conditions.

Key features:

Long subsea flowline (~120 km)

Dry gas with small volumes of condensate and water under operating conditions, and continuous MEG injection.

This field model was originally developed in OLGA 2015, during the pre-production phase of the asset. Once the field came online, we conducted benchmarking against actual pressure drop measurements. By adjusting the wall roughness from 45 to 90 microns, we were able to achieve a great match with field data (±4%) across key operating points. Given the model’s strong performance in both steady-state and transient scenarios we chose to retain the model in its original version for ongoing analysis.

However, in recent sensitivity runs using OLGA 2021 and the default roughness of 45 microns, we observed a consistent over-prediction of pressure drop compared to both field data and the 2015-calibrated model. This trend persisted with OLGA 2025, although at higher flowrates, the predicted pressure drop began to decrease, eventually aligning more closely with older results. This behaviour is consistent with patterns noted in our previous Substack post (“Flowing Uphill in Tanzania”), where newer OLGA versions tend to predict higher pressure drops under gravity-dominated, low-liquid loading conditions, and lower pressure drops at high flowrates, compared to earlier versions for gas condensate systems.

This observation supports a hypothesis that recent updates to the effective wall roughness and liquid film modelling may be overcorrecting for stratified flow behaviour in very lean gas condensate systems, particularly those with condensate-gas ratios (CGR) below 1 stb/MMscf. It's important to emphasize that this effect appears limited to extremely low CGR systems.

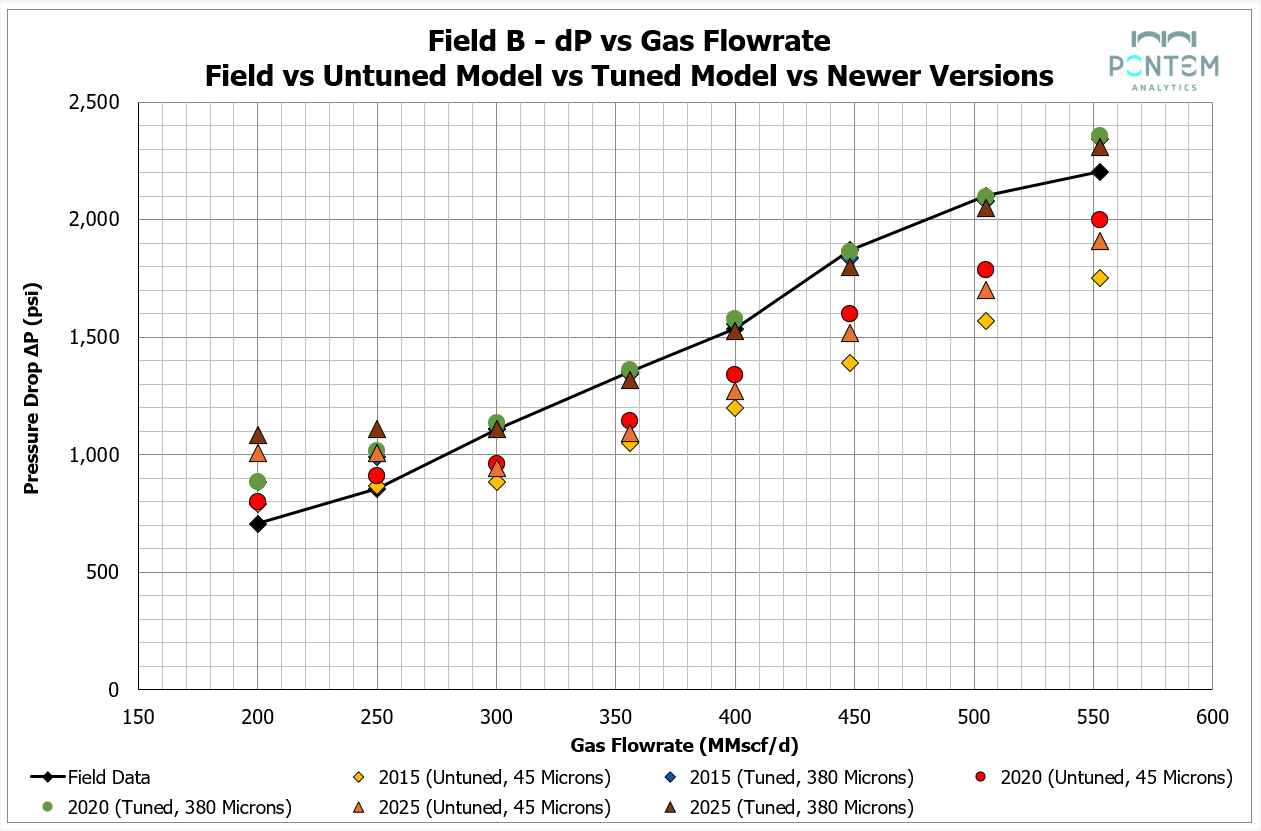

“Field B”: Large-scale gas condensate development

This field is part of a large regional gas export project, with rich gas-condensate production transported over significant distances to an onshore processing terminal. Offshore-subsea pipeline, same region as the Field A, with the main differences being the different diameter and higher CGR.

Key features:

Long (~130 km) multiphase pipeline to shore

Low CGR gas, with condensed water under operating conditions including continuous MEG injection.

Like Field A, this model was developed during the mid-2010s when OLGA 2015 was the latest available version. Once the field entered production, the model was benchmarked against field-measured pressure drops across a range of flow conditions.

In its initial state, using the default wall roughness of 45 microns, the model under-predicted pressure drops, particularly at high flowrates (>20%). To achieve an acceptable match with observed field data, the roughness had to be increased to approximately 380 microns! While this value may initially seem unreasonably high, similar tuning has been observed in gas condensate systems, where complex flow regimes and thin film dynamics affect apparent friction far more than in oil-dominated systems.

Subsequent sensitivity analyses with OLGA 2021 and 2025, using the default 45 micron roughness, showed an improvement in pressure drop prediction at high flowrates compared to OLGA 2015. Both newer versions showed better alignment with the field at the upper end of the operating envelope, reducing the pressure drop deviation to around 10%, without any roughness tuning.

As observed in Field A, the trend between OLGA 2021 and 2025 was consistent:

OLGA 2025 overpredicts dP at low flowrates more aggressively than OLGA 2021.

At high flowrates, OLGA 2025 tends to predict lower dP than 2021 .

The match at low flowrates worsened in OLGA 2025, with significant over-prediction of pressure drop. However, it’s important to note that field data at these lower rates was sparse and potentially unsteady, so it's possible that the flow regime was still transitioning and additional liquid holdup was present.

Despite the improvements in OLGA's core physics, achieving a near-perfect match with field data in this case still required tuning the pipe roughness up to ~380 microns, similar to the original 2015 model. This suggests that, in very lean systems, the apparent liquid film now dominates the wall friction contribution, effectively reducing the influence of actual steel pipe roughness. As a result, even though OLGA's default predictions have improved, they still fall short of fully eliminating the need for calibration in complex gas condensate flow scenarios.

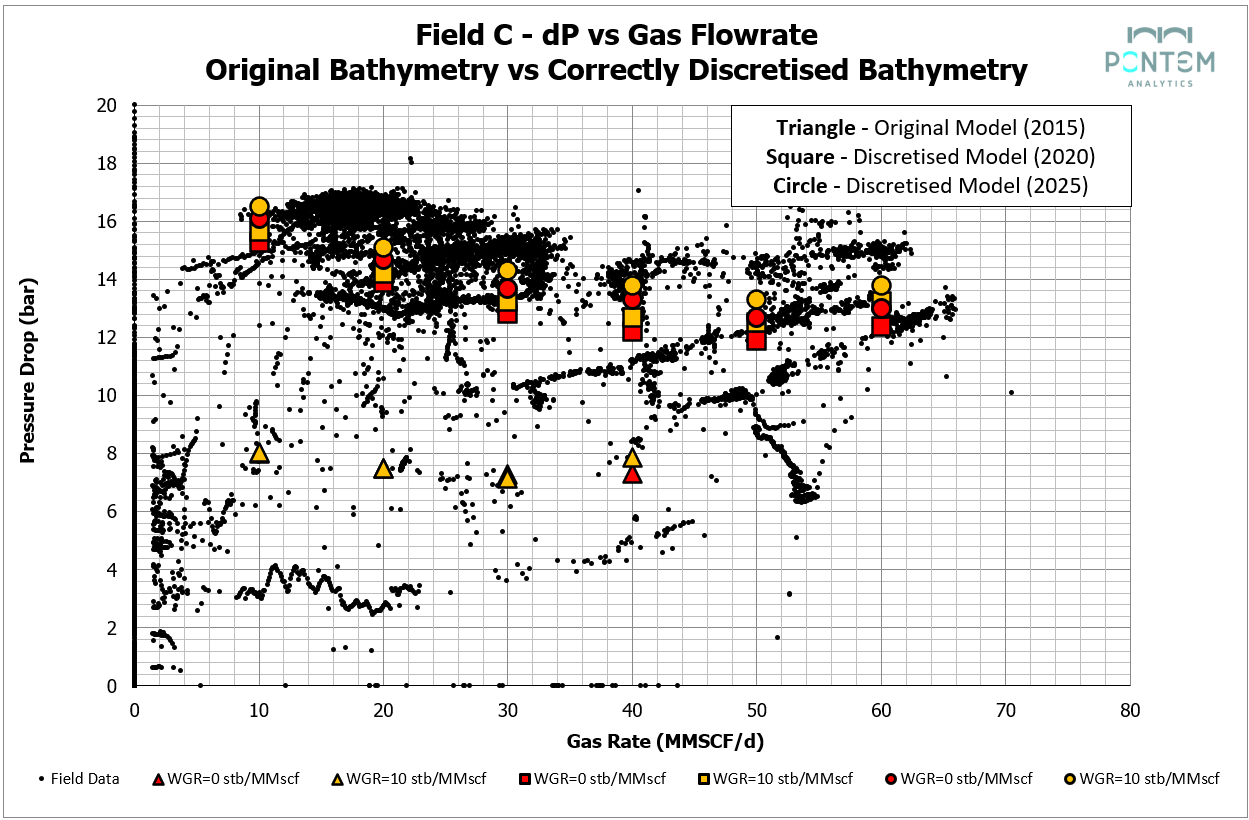

“Field C”: Long offshore tieback to onshore terminal

This mature gas-condensate field involves low-pressure wells tied back to an onshore terminal. The pipeline was designed to high flowrates, however, the field is now under very low flowrate production and is looking for either onshore compression or new tie-ins to increase the flowrates.

It operates in the lower flow envelope, making it particularly sensitive to liquid holdup, pressure drop estimation, and transient accumulation.

Key features:

Declined pressure and production rates (<8 MMscf/d)

The pipeline is >80% liquid filled.

This field presented a particularly challenging modelling environment, primarily due to the fact that it is operating well outside its original design envelope. While there are ongoing efforts to tie in additional production and implement onshore compression, the immediate objective was to benchmark the existing model and use it to support forward-looking assessments under current conditions.

The original model, built using OLGA 2017 by a third party, was provided to our team as a baseline. In practice, the model output aligned closely with earlier OLGA 2015 results.

In most systems, pipe wall roughness is a reliable tuning parameter for aligning model-predicted and field-measured pressure drops. However, this field was operating in a region where gravitational pressure drops dominated, rendering frictional adjustments far less effective.

The breakthrough came when we turned our attention to the pipeline bathymetry. In gas condensate systems, especially at low flowrates, liquid accumulation is highly sensitive to even small elevation changes. Upon reviewing the original elevation profile, we decided to replace it with as-built bathymetric survey, discretized using industry-standard methods. The result was an immediate improvement in pressure drop prediction, driven by a more accurate representation of liquid holdup distribution throughout the system.

With this improvement in place, we explored whether newer OLGA versions, specifically post-2020 releases, could further improve model accuracy. Upon switching to OLGA 2021, and later to OLGA 2025, we observed incremental but meaningful improvements in pressure drop prediction resulting in less than 10% deviation from field data.

This case reinforces two important conclusions:

The hydraulic enhancements introduced in OLGA 2025 appear to benefit gravity-dominated gas condensate systems, improving dP predictions at very low flowrates.

Accurate pipeline elevation data and proper spatial discretization are essential for valid model results in such regimes—yet often remain an overlooked source of error in legacy models.

“Field D”: UKCS subsea development with high CGR

This field consists of a UK North Sea gas condensate development tied back to a central processing facility. It operates with relatively high CGR (~40-60 stb/MMscf), with some wells producing formation water and continuous MEG injection.

Key features:

Moderate-length subsea tieback

High CGR, moderate WGR and continuous MEG injection

The examples presented in this study were intentionally selected to reflect a diverse range of operating conditions, covering different production modes, gas-liquid ratios, and flowrate regimes. This diversity allows for a more comprehensive evaluation of OLGA's predictive performance and the impact of its model improvements across various system types.

What made this Field D particularly interesting is that it featured relatively high liquid flowrates for a gas condensate system, placing it hydraulically between a conventional gas condensate and a light oil system.

The figure below compares the model-predicted pressure drops using OLGA 2015, 2021, and 2025 against actual field data across several flowrates. While the final model used for all simulation work was based on OLGA 2025, mainly due to other modeling requirements, the comparison offered valuable insights.

Interestingly, at higher flowrates, the 2015 and 2021 models appeared to match field pressure drops slightly better than the 2025 version. All three versions, however, produced results within an acceptable margin of error, indicating that the core model physics were generally sound across the board.

One key observation was that OLGA 2025 tended to slightly under-predict pressure drops at higher flowrates. While the difference was not significant enough to undermine the model's utility, it highlights how changes in turbulence effects modeling can affect pressure drop accuracy in transitional systems.

Final thoughts

Overall, OLGA continues to improve with each release, incorporating valuable enhancements, bug fixes, and feature updates that enhance its ability to replicate field conditions and support engineering decision-making. As a general principle, it is recommended to use the latest available version, especially when starting new studies, as the underlying physics and numerical stability are continually refined.

In the context of hydraulic pressure drop prediction, two major updates over the past decade have significantly influenced OLGA’s performance in low-liquid loading gas condensate systems:

2020 – Introduction of the apparent liquid film roughness model, aimed at improving predictions in annular and stratified flow regimes.

2025 – Enhancement of the HD stratified flow model through updated turbulence closures, specifically by implementing scaled apparent turbulent eddy viscosity terms on both sides of the gas-liquid and liquid-liquid interfaces.

Despite these improvements, there is still room for refinement. Our benchmarking results suggest that OLGA 2025 tends to over-predict pressure drops at low flowrates, where gravity effects dominate, and under-predict at higher flowrates, compared to earlier versions. In contrast, OLGA 2020–2024 versions generally provided more balanced predictions at higher rates, often more consistent with observed field data across a range of gas condensate systems.

Importantly, regardless of software version or theoretical improvements, all models must be rigorously benchmarked against actual field data once it becomes available. No software update can substitute for calibration using real operating conditions. A model is only as good as its assumptions, and even the most advanced simulator will diverge from reality if it’s not grounded in high-quality, field-verified inputs.

As OLGA continues to evolve, understanding how each version behaves, and validating it against real systems, remains essential to producing reliable, fit-for-purpose simulations.