Tin (10) Anniversary

Katy Lab Origin Story: Stubborn, Stupid or Sage?

This week marks the 10th anniversary of a big milestone for some at Pontem (and one ‘ex-janitor’, IYKYK). It formed the premise for a company looking to ‘bridge the gap’ between two different, but related fields, in a past life. But, a similar ethos to what we carry forward now with Pontem (and actual project carry-over too, 10+ years in).

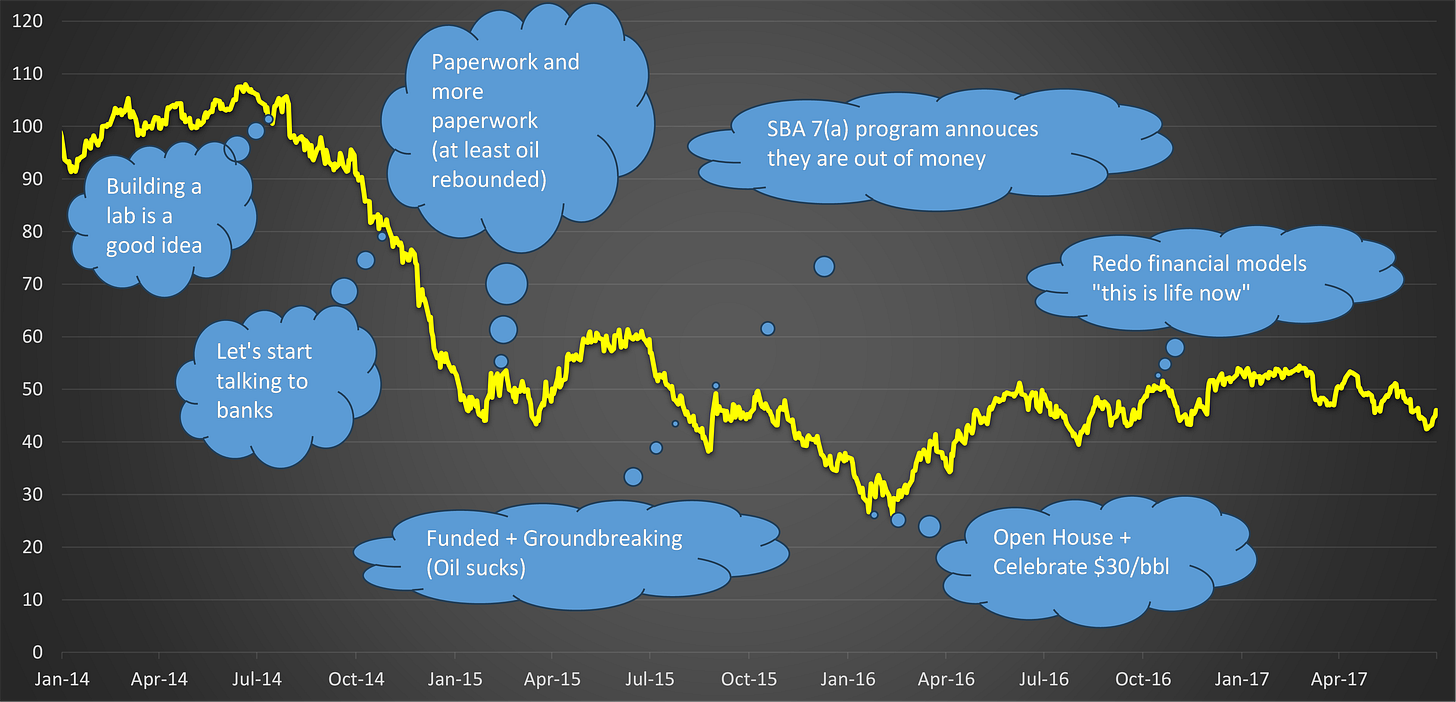

Trivia Question: Since 2010, what is the largest 6-month drop in WTI oil price?

You may be inclined to say the COVID drop of March 2020. Depending on your math, you could be right (there is clearly a 6-month window, ending 20-April at -$39/bbl, that would be pretty miserable). But, a relatively quick snapback mutes that argument somewhat. From a sustained downward trend perspective, this belongs to late 2014 / early 2015, where oil steadily slid from $105/bbl to $40/bbl (and further into sub-$30 territory the following year). That is where this story starts. Maybe not the ideal time to go into debt and try a startup.

Ten years ago this week (July 2015), three important events happened that impacted the career trajectory of several of us now at Pontem:

We signed paperwork to finance our goal of building a world-class fluids testing laboratory at Assured Flow Solutions (now SPL).

The SBA 7(a) program that we used ran out of money (SBA 7(a) Program Runs Out of Money), over the very next weekend, and most banks stopped lending to anyone in the ‘oil/gas space’.

We broke ground on the laboratory in a then-empty grassland in Katy, TX.

From our Grand Plan to our Grand Opening, oil had lost more than $85/bbl. In that price climate, we were either stubborn, stupid, or sage. Probably all of them.

We’ll take an interesting BTS look at some of the construction and build-out. From the groundbreaking, it was the usual scramble to get the lab built (a) on-spec, (b) on-budget, and (c) during hurricane season.

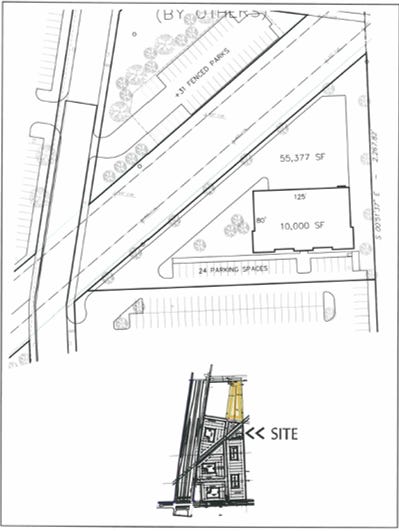

Fun Fact: The plot of land we secured was effectively ‘No Man’s Land’ - an oddly shaped piece of property that nobody could really figure out what do with. Sandwiched between a greenway, it presented a problem for the developer as to what could fit. Enter our vision for a stand-alone lab and a willingness to be first. And a willingness to play the long game. It allowed us to move quickly, along with a motivated builder, to see a unique opportunity where most did not.

Its likely that many who stepped foot in the laboratory had not been witness to the origin story, both for the lab and the area generally. It used to be a much quicker/easier to drive down that corridor of Grand Parkway (99).

Driving by today - filled with business buildings and apartment complexes - hard to remember how ‘empty’ this part of Katy was when we set out to build the facility. When we built the lab, we tried to merge two theories:

To truly understand field design, need to understand the fluids being produced.

To truly characterize the reservoir fluids properly, need to understand how the data will be used in operations.

Building the shell was only the first step, actually sourcing the equipment (from different providers globally) and getting the interior set-up was a bigger undertaking. The lab was designed with safety as Priority #1, but with the ability for the engineers and scientists to work comfortably. Significant ‘interior decorating’ to get the air exchanges / climate control, test result visualizations, sample storage, and many other amenities were incorporated to turn the lab into a world-class facility, which can be rare for most oilfield service labs. In fact, the air exchange was so significant our smart watches would register flights of stairs climbed when we’d go in and out of the laboratory. Our Garmin profiles looked like we climbed K2 daily!

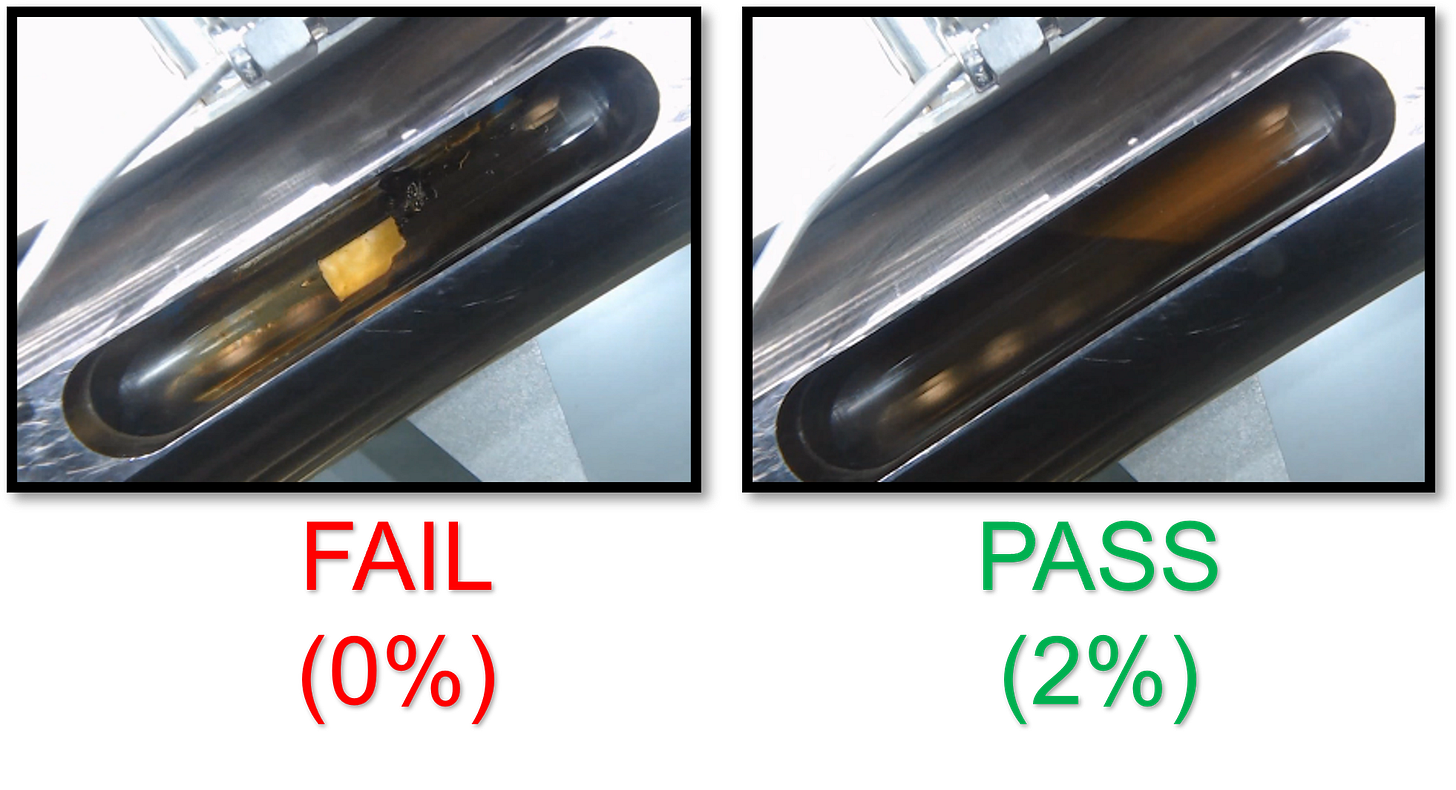

The lab rounded into shape over the 6-month construction process and by December 2015 we were running our first projects (a best-in-class asphaltene solvency qualification test and hydrate / LDHI qualification, ironically both for fields which Pontem is still engaged with today, 10 years later. Told you, long game).

During COVID, we received emergency use authorization to keep the lab (and the company) open and remain in business. We used the opportunity to make and distribute free hand sanitizer, considering we had all of the equipment available.

After emerging from COVID, there was a moment when we thought the lab burnt down (Oct ‘20). Just missed us (pictures taken from the lab across a field that no longer exists), made for a harrowing few minutes on the drive in. The lab was many things at times - enabler, differentiator, financial albatross, epicenter, frustrating, amazing, safe haven, and complicated. And almost an insurance claim (which, post COVID at times, was nearly wishful thinking!)

While the name on the building may have changed, the quality of testing carried out inside has remained first-class.

We knew when we opened our doors the initial design for our Deepwater testing facility would change. We may have been foolish enough to do all the above during the biggest downturn but we weren’t so naive to think we had installed every capability we’d need up-front. We left roughly 1/3 of the space as a warehouse knowing we’d grow into it and there were bespoke tests to develop, based on clients’ needs. And that’s what happened.

Within 5 years our bench tops were completely filled with equipment and new testing wet bench spaces and custom equipment we designed / built. The space pictured above would be filled out with additional office space, autoclaves, and a fabrication center. We were definitely building the plane as we flew it, but we held true to our vision, which we knew was serving a need for the industry. Even today, another one of the fundamental premise of the lab remains true:

In a high commodity price environment, lab testing provides additional assurance to make sure our designs are robust to future changes and can accelerate field development.

In a low commodity price environment, lab testing provides a way to optimize chemical spend and get a short-cycle ROI on reducing OPEX.

The same holds true for other initiatives (including the latest hot trends in data/AI): the ideas need to strike the right balance of where you can extract value (for service provider AND operator) across a range of commodity outcomes.

While the names and faces have changed over time - now currently run under the direction of former AFS staff - the lab stands as a testament to follow-through on a good (and risky) idea: that understanding fluids (and getting your hands dirty) was an enabler to good engineering and good field operation. We at Pontem continue this ethos today - frequently collaborating with the AFS/SPL staff on testing - to bridge the gap between all data (including lab data) and discipline.