Production Chemicals Trilogy (Part 3)

How to manage a Beauty Contest

We are coming to the end of our epic journey through the Pontem Analytics’ world of Production Chemistry but there is one final piece in the jigsaw that needs to be added. In the first part of the trilogy, we gave you an introduction to Production Chemicals and the second part showed you how to identify what chemicals to use and gave an introduction to the chemical testing process. The final part of the trilogy will be all about how you select your chemical vendor to be your Production Chemical partner. i.e the “Beauty Contest”

Sorry to disappoint but sometimes the Production Chemical “Beauty Contest” can get ugly.

Chemical Supply Strategy – How do we get to where we need to be?

Through the development process for new oil and gas fields there is a lot of work done up front to identify the chemical types that are needed. Once that has been completed (See Parts 1 and 2 of Pontem Analytics Production Chemicals Trilogy for our philosophical approach) the next stage of the process is to identify the chemical vendors to supply the required chemicals. This can be a tricky process but can add a lot of value if done well.

We now know from the previous information Pontem Analytics have shared that most if not all oil and gas systems use specialty production commodity / utility chemicals to maintain and / or enhance production. They do this by protecting the production infrastructure and equipment, by keeping the systems solids-free and flowing, by increasing the efficiency of the topsides process equipment and meeting product specifications. By doing all of that, the oil and / or gas can be exported to market and the produced water disposed of or re-injected back into the reservoir.

By recognizing the chemical requirements and identifying the types of chemicals that are needed for any new or existing oil and gas asset, the first steps in the overall chemical process have been completed. The next step is to work out where the chemicals will come from, how they will be supplied, managed and ultimately how much they will cost. This process needs the required emphasis put on it because if not done correctly a lot of value can be lost. For large oil and gas production systems the chemical costs can be $millions / year and with these fields having a working life of 20-30 years you can end up spending $100’s of millions of dollars on chemicals during the life of the field.

With these sorts of numbers being involved, it is important that the right sort of contract is in place and that all bases are covered. Therefore, identifying a suitable chemical vendor and putting in place the right type of contract involves different disciplines working together to get the best possible outcome. At a minimum the multidisciplinary team should include but not be limited to the following specialists:

1. Production Chemist

2. Operations Contract Holder

3. Contract and Procurement specialist

4. Health, Safety and Environment representative

5. Supply Chain and Logistics expert

With all the above disciplines involved you can then start the process of working out what needs to be done to get to the point where you can submit an Invitation to Tender (ITT). This could initially involve the following:

1. Identify all of the potential chemical suppliers that may be able to supply chemicals to the asset.

2. Once you have a list of the chemical vendors that may be suitable send out an “Expression of Interest” to see what companies may be interested in supplying chemicals to the project.

3. Once you know who wants to work with you on supplying chemicals. A further reduction in numbers may be needed. This can be done performing a “A Technical Pre-Qualification Process”. This is used to determine whether the potential chemical vendors have the technical capability to supply suitable chemicals and provide the required support to the asset.

4. At the end of the process there should be anywhere between 2 – 6 companies that you take forward to the Chemical Supply ITT process

Chemical Supply ITT process – The boring bit 😊

When performing a Chemical Supply ITT there are two main areas that need attention. These are:

1. The cost of the individual chemicals and supply chain that needs to be put in place to supply them.

2. The technical capabilities of the prospective Chemical vendors

Which of the above two has the higher priority will be based on the individual asset. If it is a fairly low stress system, then the cost of the chemicals will likely take priority but if it is a technically challenging system that needs people with the right experience to manage it then a chemical vendor’s technical capability is maybe what wins it for them. However more often than not it will be a balance between the two areas.

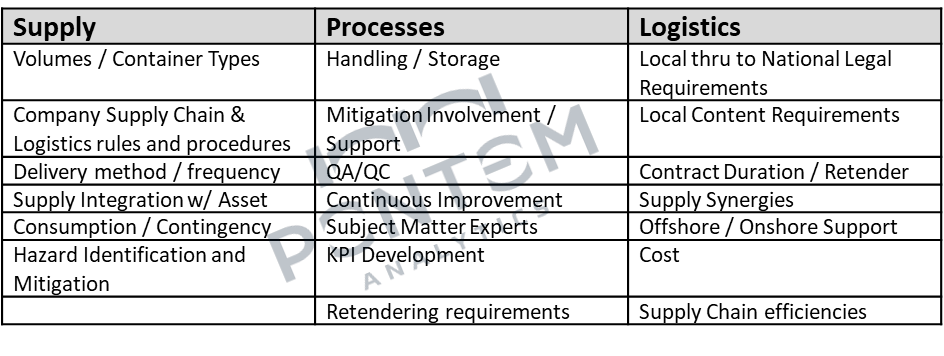

As well as the above primary requirements there are a number of secondary requirements that may need to be evaluated to determine the chemical vendor’s suitability. These should include but not be limited to what has been included in the Table below:

Making sure you pick the right chemicals!

A major document of the ITT process will be the Technical Scope of Work (SOW). This lays out the testing requirements for the chemicals that are being requested. In virtually all instances Specialty / Performance chemicals should be validated by laboratory experiment prior to selection and purchase. The exemption to this is if the severity of the problem is limited and the chemical proposed has a good track record for treating similar applications.

For lab testing, the vendor will select a shortlist of chemicals for performance trials. The specific laboratory validation program will be determined at the time of chemical selection (and may be performed by the chemical vendor, a 3rd party, or both) to demonstrate the effectiveness of the chemical but will generally include:

Demonstration of the effectiveness of the chemical in laboratory conditions as close to process conditions as possible.

Compatibility testing with other chemicals expected to be present in the system, and with materials known to be in the system.

Emulsion and foaming testing (if the process fluid is to be separated)

Effects on the produced water disposal plant (if the chemical is expected to enter the produced water system)

Environmental rating determination based on the regulations in the country the asset is located.

Stability of the chemical (particularly important in recirculating systems such as MEG, and those exposed to reboiling or distillation) to ensure that performance is maintained, and that the chemical does not form unacceptable breakdown products (such as solids, gunk or corrosive substances) even in ambient storage.

Validation tests may be repeated in a 3rd party independent laboratory to confirm results, if deemed necessary.

The performance, safety, environmental impact, practicality, and cost will be balanced to select each final chemical for deployment.

A final validation program of on-site tests should be performed shortly after the chemical is used, to verify the chemical performance, and optimize the dosage.

What type of Contracts can you have?

When it comes to the structure of the chemical contract there are three main contract structures that can be utilised. The aim is to choose a contract structure that will maximize the effectiveness of the chemical applications and the process in general. These contract types are:

Basic Chemical Supply Contract

For this type of contract the chemical vendor supplies only the chemicals, there is no service part associated with this type of contract. The Asset Operations team look after the management of the chemicals.This is only recommended if the asset has the required production chemistry expertise in house to manage the use of chemicals this will require a number of Operations personnel to be allocated to manage the use of all chemicals used in the asset. In most cases this is not a possible option due to the lack of experienced personnel familiar with the supply and use of production chemicals.

Chemical Supply and Service Contract

Here the chemical vendor supplies the chemicals and gives some support to the Asset Operations team regarding the management of the chemicals. This support may for example include monthly or quarterly visits to the platform / site and ad hoc trips by the chemical vendor when required. The Asset Operations team would still look after the daily injection of the chemicals and the overall chemical management of the system.Full Chemical Management Supply and Service Contract

For this type of contract, significant responsibility is given to the chemical vendor regarding the supply and injection of the chemicals but ultimately the overall responsibility with respect to chemicals still resides with Asset Operations Team. The additional responsibilities given to the chemical vendor can involve having a chemical vendor representative being part of the Asset Operations team. They would look after all things to do with chemicals such as performance, injection, supply, QA/QC, chemical dose rate optimisation, product development, etc. As part of this role the chemical vendor may even supply field chemists on a back-to-back basis to manage the sampling and analysis of the oil, water, and gas.

Each contract type has its merits, and the final decision will be driven by the expertise of the personnel in the asset. If there is no recognisable production chemistry expert and there is a desire to minimise staff headcount, then Option 3 is maybe preferred. If the asset already has some production chemistry capabilities, then Option 2 may be a better option. Option 1 is the least desirable option as it relies heavily on having the required production chemistry expertise inhouse along with a larger Asset headcount. Experience in the industry has shown that Options 2 and 3 usually give the best outcomes and lowest Chemical OPEX costs.

There are other types of contracts out there which from the authors perspective are less attractive, but they have their benefits sometimes. These are:

Best-in-Class, where the focus is on a single chemical application but due to the application’s size it merits its own tender process,

Preferred supplier, which is where you only ever buy from one supplier,

Tender everything, this can be messy because you could end up having to deal with multiple vendors on the same asset

Finally, similar to the preferred supplier have 2-3 vendors, which you share your global chemical business between.

When you have a field which has technically demanding chemistry issues it usually works out that the optimum chemical contract type is the Full Chemical Management Supply and Service Contract. This would ensure that the right people with the required skills are available to oversee a critical part of the operations. The aim here is to maximise system availability and thus maximise oil and gas production. This contract would involve at a minimum; the supply and management of all chemicals used in the system and any of the related equipment such as MEG Regeneration and Reclamation systems, the first fill of the chemicals into the system and the ongoing Operational requirements. This would all be done via a single chemical vendor.

The duration of such a chemical contract is usually 3 years with the possibility to extend the contract to 4 or 5 years depending on the whether the chemical vendor meets the performance criteria laid down in the contract. This type of contract is structured in such a way to maximise the chemical vendor’s performance as the vendor will want to meet the contract performance requirements to ensure they achieve the maximum length of contract on offer.

If the flow assurance and production chemicals issue are fairly minor, then Options 1 and 2 Contract types would likely be sufficient.

The Paperwork

When it comes to preparing the paperwork for the ITT process there are a number of documents that need to be created to provide information on the technical and supply chain requirements and also the contractual requirements of any chemical supply contract. With that in mind it is important to work with your procurement department to generate the required documents. These should include but not be limited to:

Specimen Contract

Company Contract Goods Conditions of Contract (CALL OFF)

Company Contract Goods Form of Agreement (CALL OFF)

Vendor Referencing Documents

Anti Bribery and Declaration form

Company Bank Detail Requirements

Company Supplier Registration Form

Miscellaneous Contract Documents

ITT Cover Letter

Invitation to Tender

Scope of Work Chemical

Remuneration

Tender Questionnaires

HSE Capability assessment Questionnaire

Security Questionnaire

Sustainability Questionnaire

Local Content Questionnaire

There can only be One!

Unlike in Highlander the selection process is a bit more mundane.

To make the most of the competition between the chosen vendors and thus minimise the costs associated with the use of chemicals. The method for selecting the successful chemical vendor is to invite the selected chemical vendors that have been chosen from the responders to the “Expression of Interest” and approved via the “Technical Pre-Qualification Process” to test and select chemicals for use in the Asset in question.

The ITT creation, chemical testing and ITT bid evaluation process is likely to take a minimum of 9-12 months, with an additional 6-9 months required after the selection of the preferred chemical vendor to ensure that everything is in place with respect to the supply and injection of chemicals into the asset.

The above process will be part of a structured commercial tendering process, which will also involve the chemical vendors providing information such as:

The unit costs of the chemicals they are proposing to use,

The manpower they will use to manage and service the contract

The supply chain logistics regarding the supply of chemicals to the asset.

How they plan to manage their HSE and QA/QC responsibilities.

The supply of lab equipment, lab consumables and the manpower requirements needed to run the lab effectively (Optional depending on requirements)

There may be other requirements that are asset specific to the individual assets but these should be identified during the ITT process / discussions.

Once each of the vendors have completed their testing and submitted their proposals, these will be evaluated by the Asset Operations team. At the completion of the process a single chemical vendor will be chosen that meets best the HSE, Technical and Commercial requirements of the asset.

Once that is done the fun can begin.

Epilogue

We have now come to the end of the Production Chemical Trilogy. In Part 1 we introduced you to the world of Production Chemicals. For Part 2 we were able to take you through the process of what was needed to test them and finally in Part 3 we were able to give you instructions on how to find your preferred Production Chemical partner. This has taken Pontem Analytics over 30 years to get to this level of understanding so don’t worry about becoming an expert overnight. We are here to help you along your journey of Production Chemical Enlightenment.

There is a lot to take in but if managed correctly, the effective use of production chemicals can transform how you operate your oil and gas fields.

However, like Gandalf we haven’t given away all our secrets, so if you want to get to the top of the pile, Pontem Analytics is here to support you. We will get you to embrace production chemicals (figuratively of course) for the great help that they really can be.

Please reach out to info@pontemanalytics.com to discuss how we can help solve your business’s most important problems!