Pontem Analytics: Paraffin Quiz

Welcome to the House of Wax

We had a lot of fun with our Pontem Hydrates Quiz so we thought we would do the same for Wax.

Like hydrates, there are lots of things that you need to think about when trying to determine how much of a problem wax is going to be and if it is, what the best solutions are to manage it. The aim of the Wax Quiz is to help you as budding Flow Assurance engineers or even seasoned pro’s navigate the shark infested waters that are the design requirements associated with managing wax.

With that in mind let’s get started and in my humble opinion the best place to start is the wax characterization of a new fluid taken from an oil or gas well.

When you want to understand the temperature at which wax may deposit in a system what property of the oil are you most interested in?

A. Viscosity

B. Wax Appearance Temperature

C. Wax Dissolution Temperature

D. Pour Point

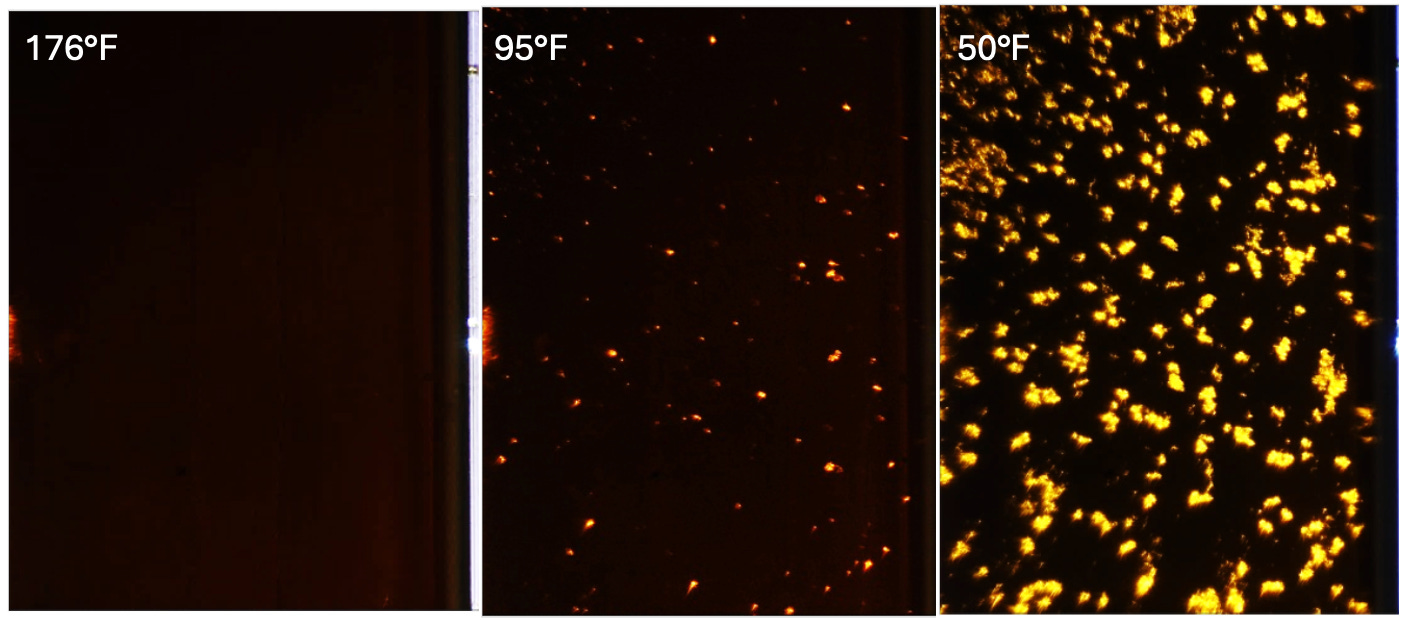

One of the most important properties of the oil when evaluating a wax problem is the WAT and one of the most common methods for determining the WAT is CPM. What does CPM stand for?

A. Crude Pour Moment

B. Critical Point Monitor

C. Crude Paraffin Match

D. Cross Polar Microscopy

At the temperatures above where the wax first comes out solution the oil is a Newtonian fluid the temperatures below this point the crude oil is a Non-Newtonian fluid which behaves like a Thixotropic fluid. What is a Thixotropic fluid?

A. A viscous fluid that becomes less viscous when subject to shear force.

B. A viscous fluid that becomes more viscous when subject to shear force.

C. A viscous fluid whose viscosity doesn’t change when a shear force is applied.

D. None of the above.

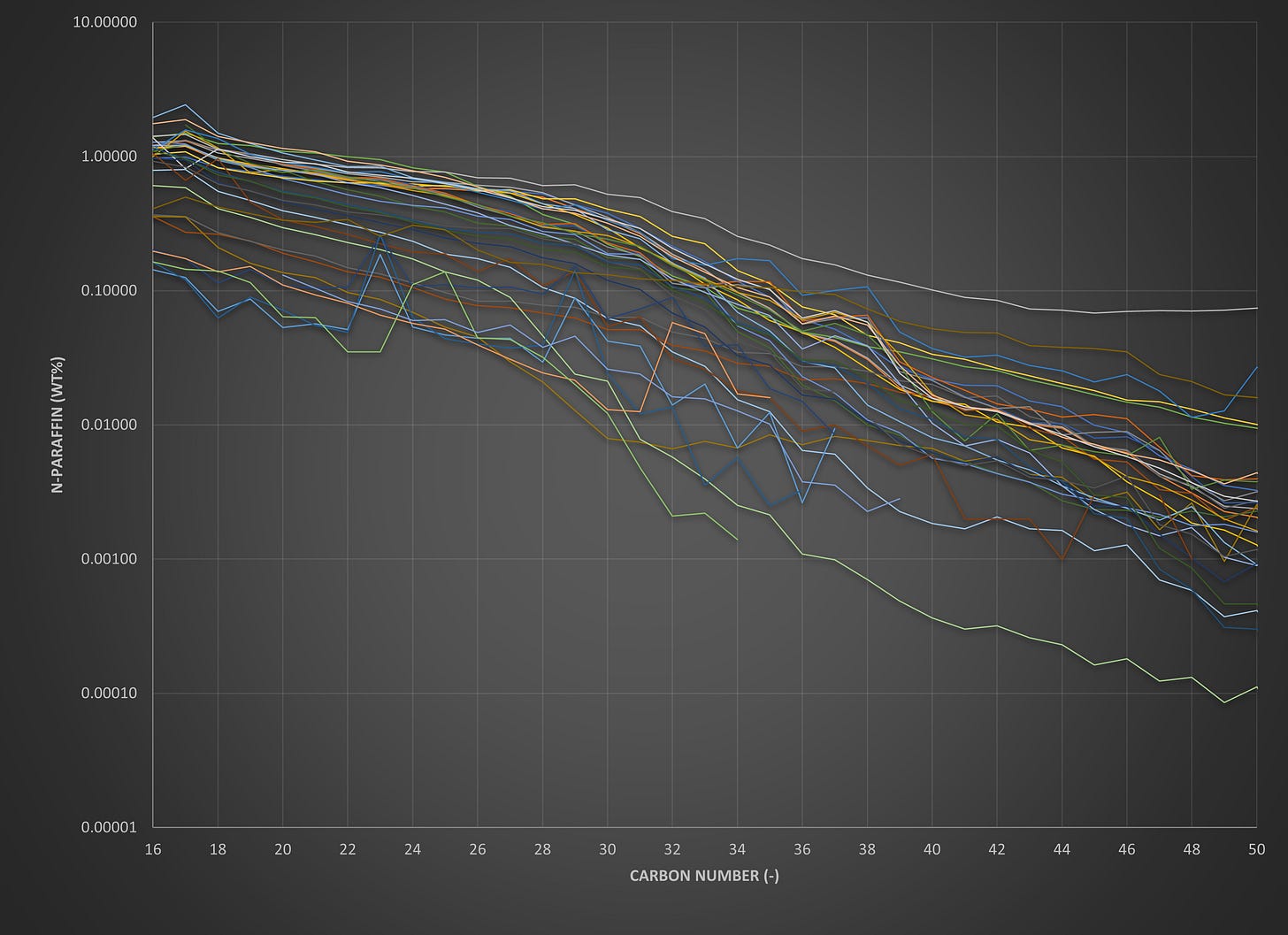

What chromatography method is used to measure the n-paraffin content of crude oils, which is then in turn used when determining wax deposition rates?

A. HTGC

B. HPLC

C. IC

D. TLC

When determining the pressure needed to restart a pipeline filled with gelled oil. What property of the oil do you need to know?

A. Upper Pour Point

B. Lower Pour Point

C. Yield Stress

D. Wax Appearance Temperature

It is important to measure the viscosity of the oil before and after wax starts to come out of solution in a oil export pipeline. What are the main two properties that will be impacted as the oil goes deeper into the wax region?

A. Wax deposition rate and pressure drop across the pipeline

B. Temperature drop and flow regime

C. Fluid velocities and temperature

D. All of the above

In ASTM D5853 - A Standard Test Method for Pour Point of Crude Oils you measure an upper and lower pour point. What is the main difference in the test methods used to measure the upper and lower pour points?

A. Test pressure

B. Test mixing

C. Test height

D. Test temperature

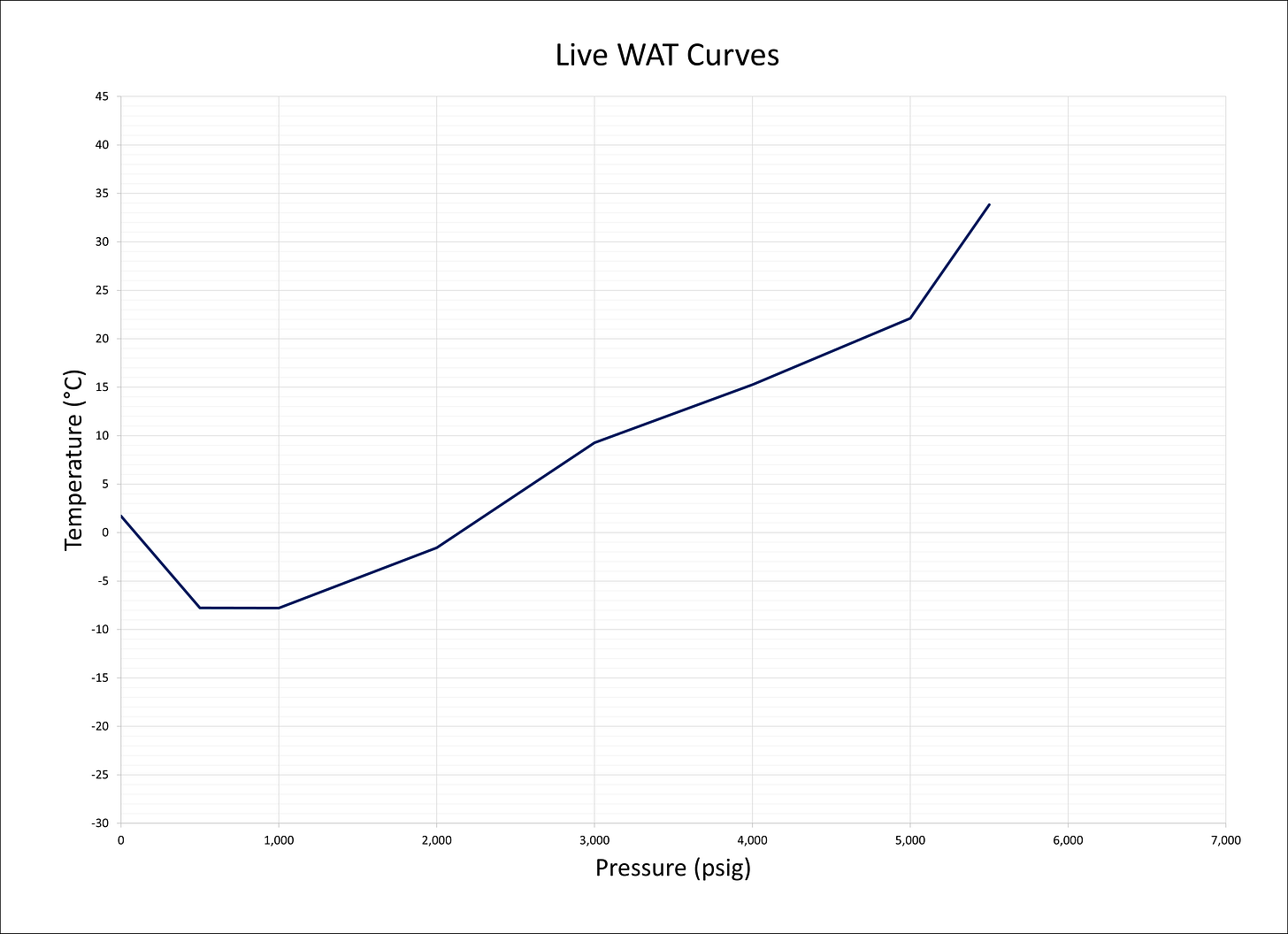

It is important to understand how pressure effects the WAT. In multiphase system that are under saturated in gas increasing pressure decreases the WAT. Why is this the case?

A. It increases the solubility of gas in the oil phase increasing the solubility of the wax components.

B. Makes the wax inhibitor work better

C. Increases the viscosity of the oil

D. None of the above

For a stabilized oil that is being exported via a subsea pipeline if it drops below the WAT and the pressure of the system is increased to 100bar. What will this do to the WAT that was measured at STP?

A. Decrease it

B. Increase it

C. It will stay the same

Differential Scanning Calorimetry (DSC) can be used to measure WAT of an oil. How does it do that?

A. It measures a change in the weight of the oil sample as the sample is cooled.

B. It videos the point at which you can see the first wax crystal forming

C. It detects small changes in temperature caused by the wax crystallisation process as the sample is cooled

D. It measures the pressure drop across a fine filter as the sample is cooled

Once you know as much as you can about the wax characteristics of the oil. You need to use this information to understand how this will affect the operation of the system you are looking at. So to help with that we have come up with some questions to get you thinking along those lines.

11. If you have a crude oil export flowline transporting a waxy crude oil at an ambient temperature of 4°C and the crude oil entering the systems is also at 4°C but has a WAT = 40°C and a pour point of 0°C. What will happen with respect to wax deposition.

A. Wax deposition should not be an issue

B. The oil will not flow because it has gelled

C. There will be significant wax deposition throughout the pipeline

D. Wax will only deposit at the start of the pipeline

12. There are two main benefits of insulating a flowline when it comes to wax deposition. The obvious one is that it keeps the fluid temperatures hotter. What is the other benefit?

A. Increasing the flowing temperatures decreases the oil viscosity.

B. Reduces the temperature difference between the inner surface of the pipeline and bulk oil flowing temperature

C. Helps wax inhibitors work better

D. Stops gelling from occurring

13. If you have two crude oils, A and B and they both have a WAT of 35°C, wax content of 10% and are producing at the same rates, temperatures and pressures inside the wax region but Crude A is twice as viscous as Crude B, which crude oil will have the worse wax deposition?

A. Neither, they will be both the same

B. Crude B

C. Crude A

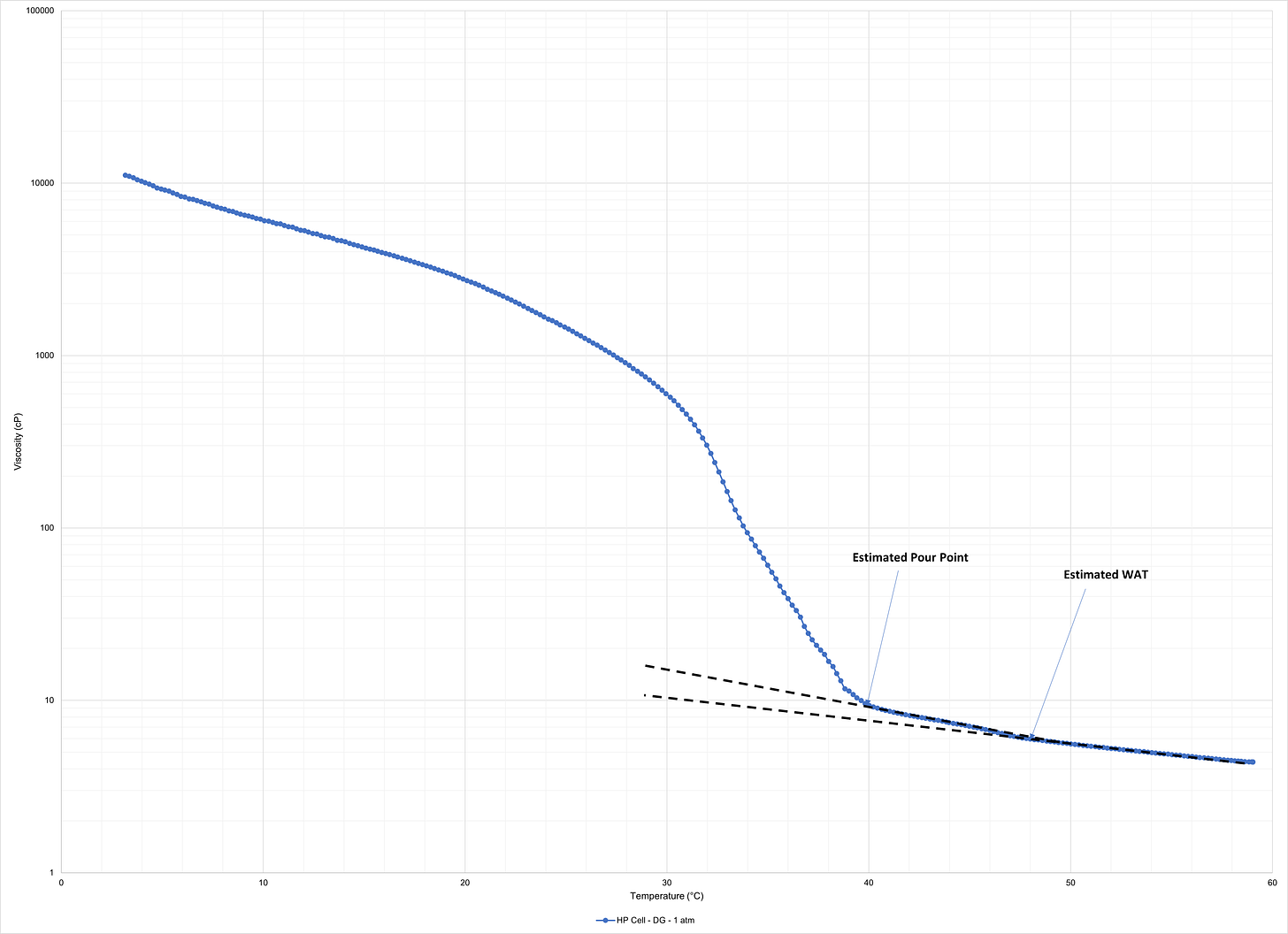

Top Tip - Viscosity Curves can be used to estimate the Oil’s WAT and Pour Point

14. What component of the oil most impacts the wax characteristics of the oil?

A. N-alkanes from C5 to C15

B. Naphthenates

C. Resins

D. N-alkanes >C15

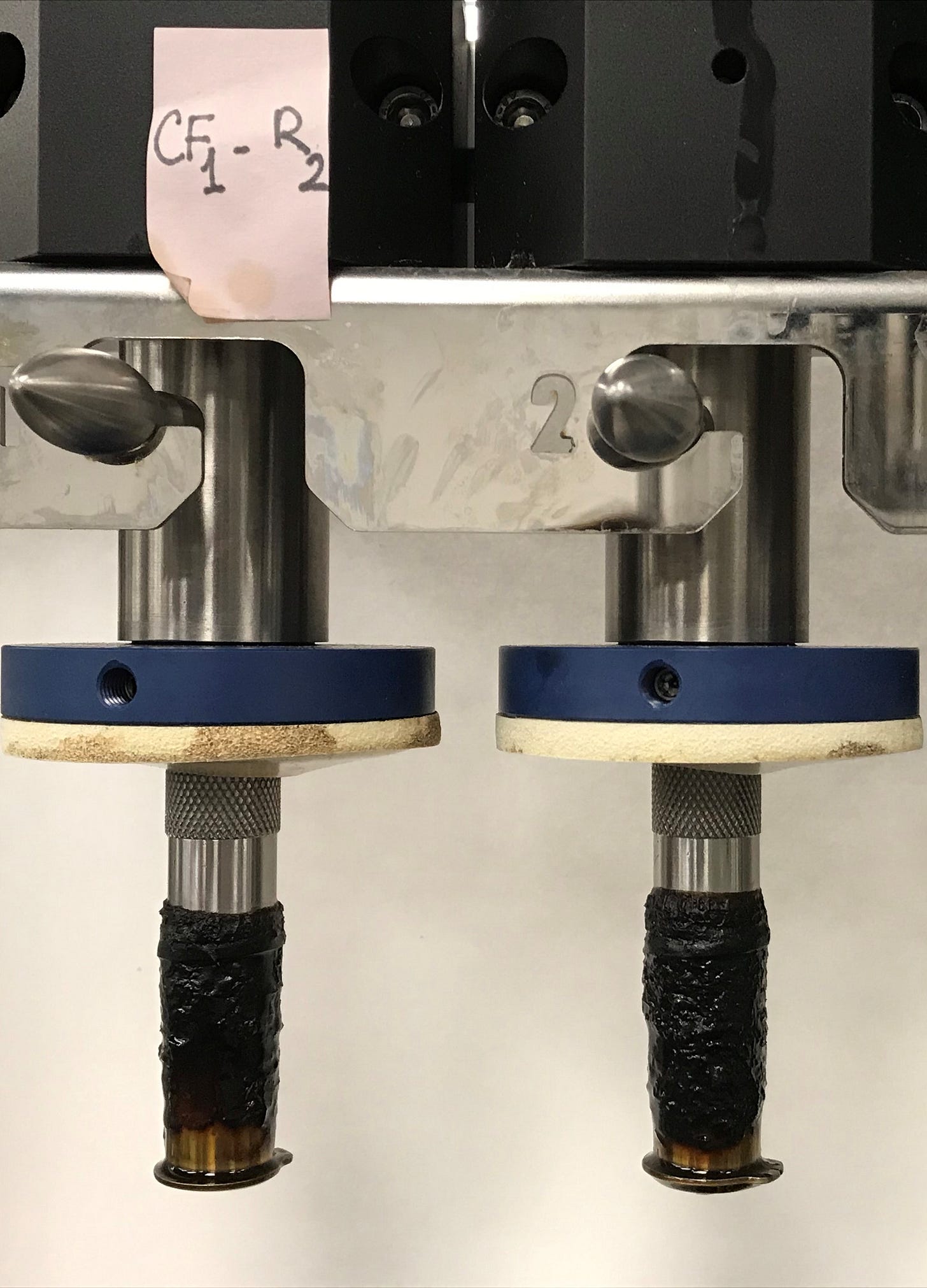

15. Pigging is an operational tool used to remove deposited wax and to prevent the wax removed by the pig from building up in front of it during the pigging process a specific type of pig is recommended. What is this?

A. Foam Pig

B. Bypass Pig

C. Intelligent Pig

D. Gauge Pig

16. When determining how often you need to pig what are the two main components that you look at?

A. The wax deposit thickness and/or total wax volumes/mass that could be removed

B. The type of wax that gets removed

C. The length the wax is deposited along the flowline

D. The time it takes to pig the line

17. The graph below is a very useful tool when determining the severity of the wax deposition problem. What is it called?

A. HTGC curve

B. WAT curve

C. Wax and Gelling curve

D. Wax Precipitation Curve

18. Another method to remove deposited wax from a system is to use a hot fluid such as oil or water to melt the wax or to use a chemical that can dissolve the wax. One of the most common chemicals used for this is:

A. Methanol

B. MEG

C. Xylene

D. TEG

The following equation is very useful when dealing with waxy crudes. What is it calculating?

A. Gel Restart Pressure of a pipeline

B. Wax Deposition Thickness

C. Wax Inhibitor Dose Rate

D. Viscosity of the oil

In gas condensate systems a JT cooling effect is possible due to the large pressure drops and gas expansion. In some instances, there are certain flowline sections where the fluid temperature is lower than the ambient temperature, which results in the wall temperature being warmer than the fluid temperature. Assuming that we are operating at <WAT, which of the below is true:

A. If the temperature of the pipeline wall is <WAT, only then the wax can continue depositing.

B. As the fluid temperature is <WAT, deposition of wax is still expected.

C. Wax will continue precipitating, but not depositing to any significant extent.

D. Wax will continue depositing and precipitating.

Hopefully that has been both fun and educational. We have tried to keep the questions nice and easy so you don’t have to work too hard. Because when it becomes serious you will know to call the “Waxbusters” that are Pontem Analytics.

As before with the Hydrate Quiz, there is only one rule, the Quizmaster’s decision is final and you will have to read our next post to get the answers.

Please reach out to info@pontemanalytics.com to discuss how we can help solve your business’s most important problems!