Polar Opposites: Global Project Update

A Penguin and a Polar Bear walked into a Bar......

We are extremely lucky at Pontem Analytics because we get to work on very diverse projects. This can be from a fluid, pressure, temperature, sea depth and onshore / offshore perspective…but it can also be from a geographical perspective.

We have had the pleasure of working on one of the most southerly oil developments in the world near Antarctica, while also one of the most northerly oil developments located in the Arctic region of Alaska.

Both have their challenges caused by their remote location, environment and the weather around them. This not only impacts how they will be developed but also how they are operated. When looking at the various flow assurance and production chemistry issues that may need to be managed, in cases like this where the fields are, can impact the solutions that are identified.

These fields may be at different ends of the earth but there are also some similarities between the fields. They are both:

1. Oil producing fields

2. Remotely located and are likely to be affected by extreme weather events

3. Require seawater injection to maintain reservoir pressure and improve overall oil recovery

4. Use gas lift as an artificial lift method

5. Need to maintain flowing temperatures as high as possible for varying reasons

Going South

Over the years myself and some of my Pontem colleagues have worked on a remote offshore field in the South Atlantic. The main challenge, out of many diverse challenges for this field was to find out how best to manage the crude oil with a wax content >20% that is produced from subsea wells in 450m of water. That was certainly challenging enough but thankfully we didn’t have to try and figure out how best to dodge any stray icebergs that may find their way to the vicinity of the field, that was somebody else’s job.

Solving the problem of the extremely waxy crude has taken the project to the verge of unlocking the very attractive economic prize at the end of the development process. This South Atlantic field has:

1.7 billion barrels oil in place

Independently audited 500 million barrels of 2C recoverable resources in the first field to be developed

Highly appraised leading to a well understood reservoir

Highly marketable crude.

You may wonder why a crude with such high wax content is classed as highly marketable when it is really quite difficult to get out the ground. Well, what makes it a challenge from a flow assurance perspective i.e. the high wax content, makes it more valuable to refiners. The wax itself once refined can be used in many different products such as candles, wax paper, polishes, cosmetics, and electrical insulators. It also assists in extracting perfumes from flowers, forms a base for medical ointments, and supplies a waterproof coating for wood.

Petroleum Jelly - One of the many uses of wax taken from crude oils

With such a high wax content crude oil, it isn’t ideal that the field is situated at a water depth of 450m, with the minimum ambient sea temperatures at that depth being as low as 3-4oC. This is because at these temperatures the oil becomes solid due to the wax. This also makes it difficult to transport long distances so any commercial trading tanker that takes the crude from the FPSO must have the ability to keep the oil warm. This also goes for the field’s FPSO. You can’t sell the crude if you can’t pump it out the FPSO storage tanks.

In reality compared with the Arctic field, the South Atlantic field does not have such extreme temperatures, but sea conditions and the remoteness of the site probably make up for that. The nearest onshore site is 200km away, with the next closest probably being in the region of 350km.

This may seem like a tough flow assurance nut to crack but the project had the knowhow to evaluate the physical properties of the waxy crude oil in the lab to make sure the project knew exactly what they could and couldn’t do with the oil and as luck as it a lot of this expertise now resides in Pontem Analytics.

Unlocking the Puzzle that is Wax

The wax characterization data was used as input into the flow assurance models used for the design of the system. This help us to understand how the waxy crude oil would behave when it cooled. This then allowed the project team to ascertain the best way to operate this system to easily produce oil reliably from the reservoir to the processing facility.

To produce this waxy oil, the focus was on “thermal management”. To optimize this, the design includes highly insulated subsea flowlines, the location of the processing facilities near to the subsea wellheads, the ability to inject a wax treatment chemical, heated seawater for injection, heat traced topsides piping and heated FPSO crude oil storage tanks. All of which have helped reduce the impact of the wax and set up the project to easily deal with whatever is thrown at them.

The project got to this point by gaining a thorough understanding of the flow assurance issues, how the multiphase nature of the fluids helps things and by using our favorite flow assurance software, OLGA to closely evaluate where the oil accumulated in the wells and flowlines. This has helped to show that there will never be a situation where a long wax candle forms in the subsea flowlines or wells that couldn’t be removed. This approach has allowed the project to get to the point, where confirming the Final Investment Decision (FID) in 2024 is a distinct possibility.

The type of expertise required to get to this point sits very much in the wheelhouse of Pontem Analytics. We have some excellent SME’s when it comes to everything involving wax. I myself have spent nearly 15 years dealing with some of the trickier wax problems the oil and gas industry has to offer.

If a more conservative, less pragmatic approach had been taken, confirming the technical feasibility of the development may not have been so straightforward.

Northern Exposure

As for the Arctic field, that presented a different challenge. For onshore Arctic developments, not only do you have to find answers to the usual flow assurance questions you also have to find ways to deal with the extreme cold temperatures experienced during the winter months which in this case were as low as -50oF.

It is not all plain sailing in the summer months either because from an installation, construction and operational perspective you have to deal with the waterlogged landscape which can make it difficult to move heavy equipment via the temporary project roads. There is so much mud about on the roads you may end up getting stuck it.

The field that Pontem is working on represents one of the largest conventional oil discoveries in the United States in the last 30 years, and the current phase of the project is the most significant development on Alaska’s North Slope in more than 20 years.

And there is certainly no lack of oil, the reservoir in Phase 1 of the project is estimated to contain 768 million barrels of recoverable oil.

The project has strong fundamentals and is located in a world-class oil producing province with significant existing infrastructure, has low unabated emissions intensity and is supported by key stakeholders, including the State of Alaska, the North Slope Borough, the landowner company Kuukpik Corporation and the Arctic Slope Regional Corporation (ASRC).

The field’s operator expects first oil to flow at rates up to 80,000 bbl/d by 2026, diversifying their portfolio and increasing their global footprint.

Laying a flowline in the Arctic Winter

During our work on the project, Pontem identified a number of flow assurance risks associated with production from the field, with one of the main risks being hydrate formation but unlike most fields it is not only hydrates that need to be dealt with but ice formation in not only the production systems but also the water injection systems. When you have winter temperatures as low as -50oF it is quite easy to form ice when you have water that isn’t inhibited with Methanol. The following video shows that.

Other areas of concern include wax and gelling but thankfully they are nowhere near as severe as we see in the South Atlantic field we have worked on. Additional areas that need attention are emulsions, scaling, corrosion and the impact of H2S production due to souring of the reservoir caused by the injection of seawater. This could exacerbate any corrosion and could result in solid handling issues if large amounts of Iron Sulphide are produced and need to be removed from the system. Interesting fact about Iron Sulphide is that it is pyrophoric in nature so when removed from the system and exposed to the atmosphere if not kept wet it can result in spontaneous fires occurring due to the heat that gets generated. H2S also presents a HSE concern due to the toxic nature of the gas. Anything between 10-500 ppm of H2S, can cause various respiratory symptoms that range from rhinitis to acute respiratory failure. Anything above 500ppm is likely to kill you.

You even have to keep an eye on the chemicals you use as they could freeze as well.

Supply Chain Conundrums

The remoteness of both fields has led to a lot of thought going into supply chain issues. No point in choosing a flow assurance control method such as a chemical that you can’t get delivered to the field in a timely manner or that is not stable at the ambient temperatures it is likely to see. This is definitely more of the problem for the Arctic field as it is not so easy to identify suitable chemical products that won’t freeze during the winter if left outside. To combat this, the Arctic project has included a heated chemical storage facility.

When it comes to ensuring you do not run out of chemicals to inject, it is important to decide upfront how long it takes to get chemicals onsite and from that information decide how much chemical needs to be stored at the field’s supply base.

Environmentally Responsible Engineering

For Pontem, doing what we do isn’t all about getting the oil out of the ground, we appreciate the opportunity to see what each location we work in has to offer. Where the South Atlantic and Arctic fields are situated, the environments are pristine and teaming in wildlife.

Consequently, both operators have made a significant effort to protect the environment. The South Atlantic field is committed to protecting the amazing wildlife to be found there by re-injecting all produced water and gas and minimizing emissions.

For the Arctic field, focus has been placed on reducing emissions such that it will be globally one of the best oil and gas development with respect to greenhouse gas emissions performance. They too have also included the re-injection of all produced water and gas. They even have a facility that allows for all drill cuttings to be ground down and disposed with the produced water.

By minimizing emissions this goes a long way to reducing the risks of the project adding to global warming. The operator is committed to delivering a net-zero project and is working with the local communities to provide carbon offset projects such as a forestry management project, carbon abatement solutions, and carbon capture systems. This includes working with a leading regional company on developing low carbon solutions in the Arctic.

As well as minimizing their environmental footprint at their respective locations. Both operators are just as importantly looking to make a difference to the economic development of both areas. With the aim of significantly improving the standard of living for the local residents.

Animal Bingo

With respect to the wildlife the animals present are quite different at each location but amazing in their own way and certainly worth a game of animal bingo where the aim is to spot as many of the indigenous wildlife as you can.

For instance, if you like penguins the South Atlantic field is the place to go. The following are some of the penguins you might see if you visit the location.

Rockhopper Penguins

King Penguins

Gentoo Penguins

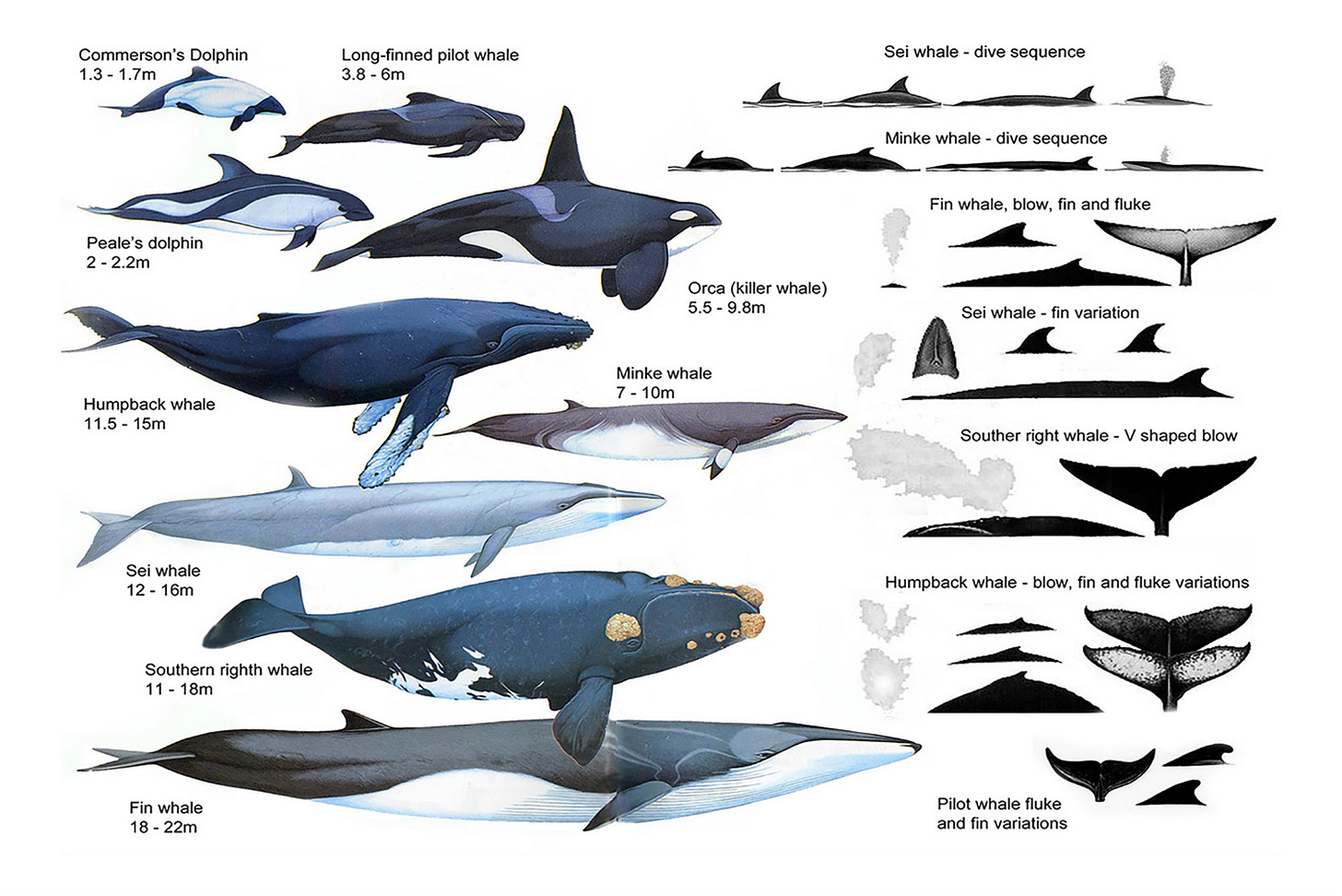

If you want to see something bigger. There are plenty whales, dolphins and porpoises that are active in the area of the South Atlantic field as they are attracted to this area by an abundant food source, especially squid. Interesting fact, a large percentage of the squid we eat in the world is caught in this area.

Finally, you have various types of seals, some more cute than others.

With the Arctic field being onshore, the wildlife is less marine centric but definitely just as interesting. Some of the larger mammals that you will find are:

Caribou

Muskox

Arctic Fox

Polar Bear

With a lot of people having a soft spot for polar bears, unless of course you actually meet one in the wild, here are some remarkable facts about polar bears

Polar bears are one of the world’s largest carnivores. Adult males weigh about 1,500 pounds and can be almost 10 feet tall when standing on their hind legs.

Polar bears’ favorite food is seal, and they eat an average of 4.4 pounds of seal fat every day.

Polar bears have a strong sense of smell. This trait helps them to sniff out hidden seals up to 20 miles away and through three feet of solid ice.

Polar bears are great swimmers. They have a relatively small head and partially webbed toes, which help them move easily through the water.

Polar bears are perfectly adapted to cold temperatures. They have black skin to absorb as much heat as possible, and short ears and tails to help keep that heat in their bodies.

This post does not have as many useful Pontem technical gems as normal but we thought it was worth sharing to show the diverse nature of the projects we work on from a geographical, environmental and wildlife perspective. It is just another facet of what makes working in the oil and gas industry so fascinating and enjoyable. It is not all about nerds in lab coats.

We will keep updating you as these fields progress, as they are major sources of oil production due to come online in the future. In some cases, they will be transformative to the region. In others, an opportunity to continue the long-lasting legacy of one of the world’s premier basins.