Listening to the Pipeline

Wax, Data, and the Final Years Before Decom

When a field nears the end of its life the story isn’t over, it just changes chapters. In our case, the last few years before the final barrel aren’t about chasing production records, they’re about listening closely to what the pipeline is telling us and making sure it can retire gracefully with minimal cost, minimal risk and minimal environmental footprint.

The Late Life Question

Decommissioning is often viewed as a demolition job…

In reality, the real work starts years earlier in quiet data‑driven decisions that shape how that final chapter will unfold.

Right now, one question looms large:

Will wax build‑up in the pipeline become a problem before we shut down?

And, if so, what would that mean for decom, technically, economically and environmentally?

The Challenge

We have:

A long subsea tieback.

No pigging option.

Declining rates that will eventually push arrival temperatures below the wax appearance threshold.

That’s a recipe for deposition. Without the ability to mechanically clean the line, we need to know, with confidence, whether wax will start to accumulate to the point of trouble before cessation of production.

A Hybrid Approach to Monitoring

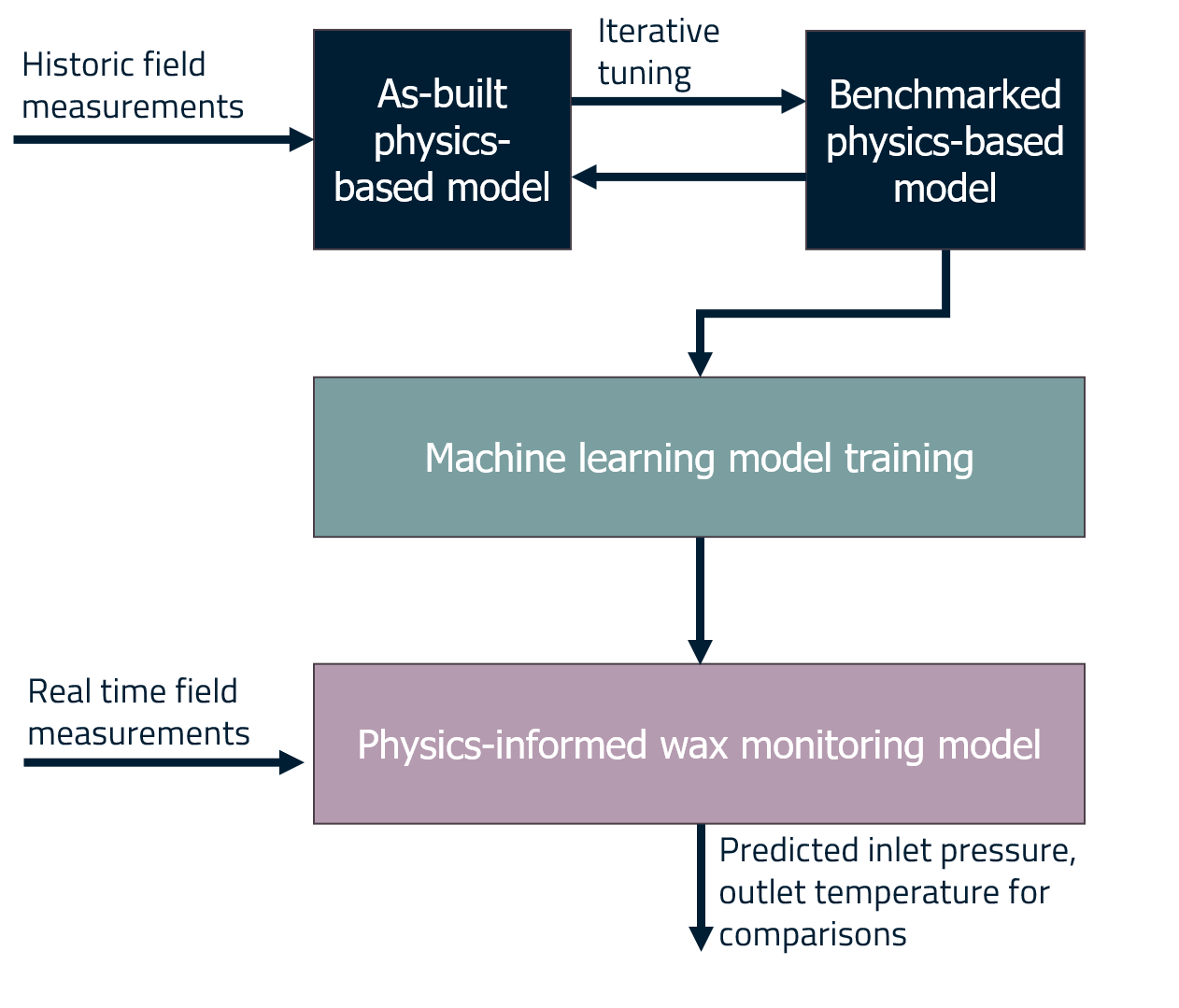

We’ve paired two worlds:

Physics‑based modelling: a thermal‑hydraulic model tuned to the asset.

Machine learning: trained on hundreds of simulated cases and field data to recognize the “normal” behavior of the system.

By comparing predicted vs. actual temperatures and pressures, we can spot the earliest signs of wax long before they show up in raw field trends.

Think of it as a stethoscope for the pipeline: subtle changes in the heartbeat tell us when something is starting to build.

What the Data is Telling Us

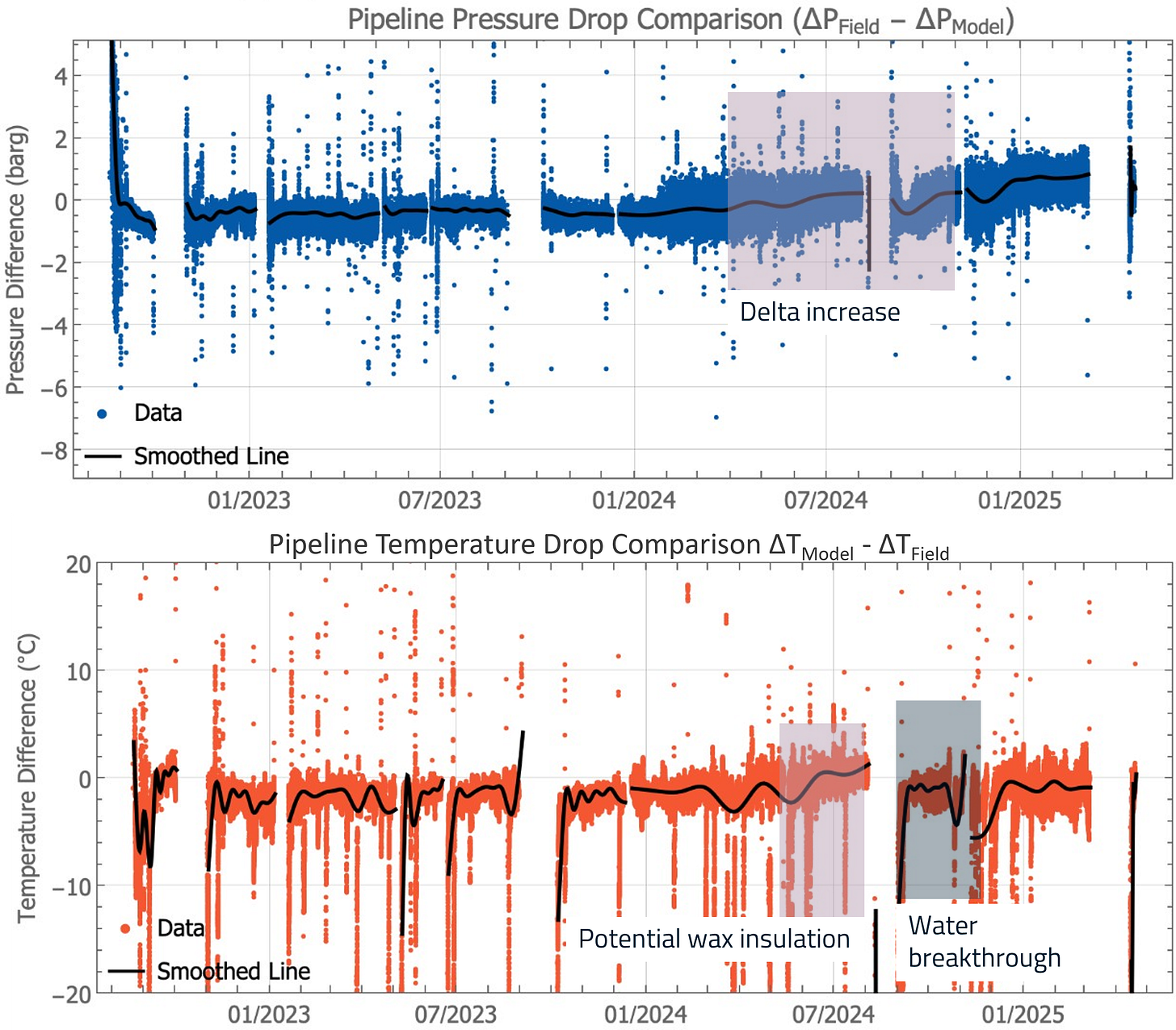

So far, the model and the field data have marched in lockstep. As rates decline and arrival temperatures dip below the wax appearance temperature, we’re beginning to see the first small deviations — more pressure drop here, less cooling there.

We used these insights to run forecasted wax deposition cases, enabling an estimation of present and future wax levels.

The forecasts say:

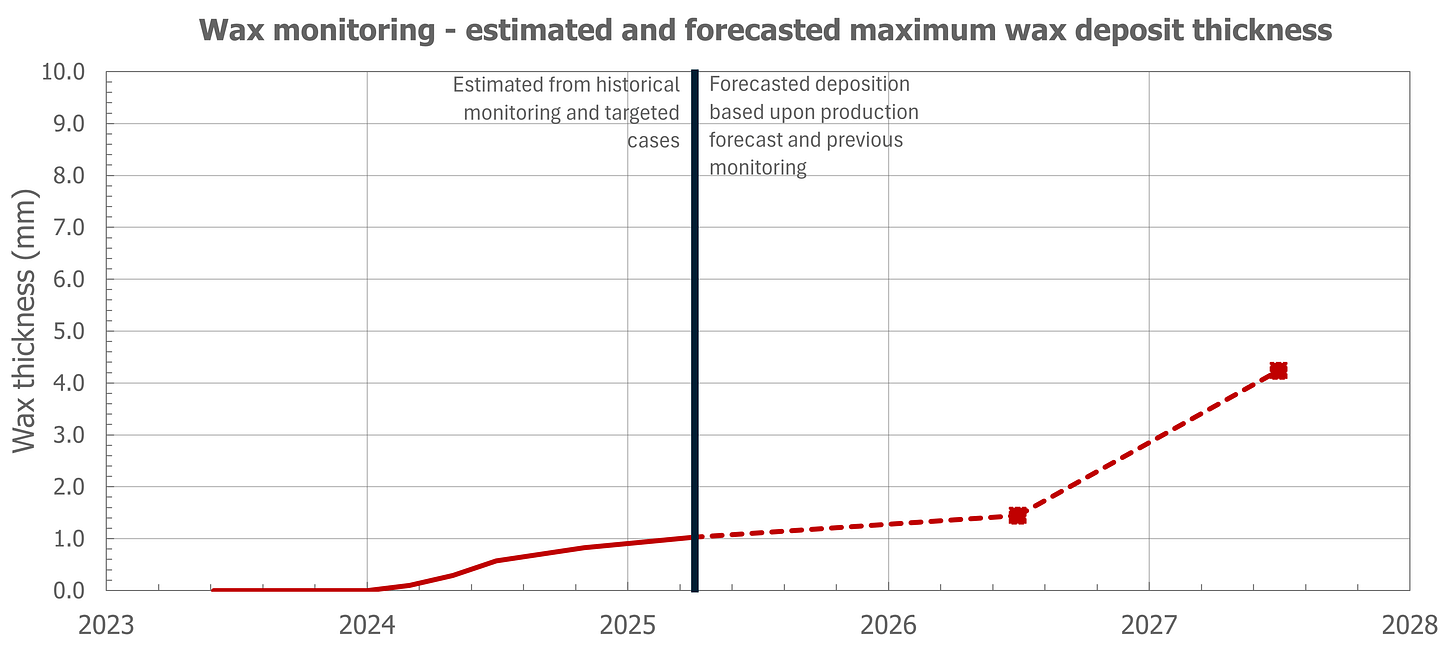

Wax has deposited and will continue to, but slowly…

By the projected cessation date in a couple of years, the total volume is expected to be less than 1% of the pipeline’s capacity.

The thickest deposits will likely be in short, removable sections near the riser.

These forecasts are built with multiple layers of conservatism, and can be continually updated as the field progresses and even more data is available. Resulting in a clear description and analysis that gives confidence that there is little operational impact to be expected.

Why That Matters for the Environment and Decommissioning Strategy

This is an environmental question as much as it is a flow assurance one.

When a pipeline reaches the end of its life, operators typically face two decom options:

Option 1: Produce Up to the Platform

Flush the pipeline by continuing production until all fluids are pulled up to the topsides.

Leaves the line clean, but at a cost.

Requires extended production, more offshore time, and higher decom spend.

Option 2: Push Down into the Reservoir

Instead of pulling everything up, fluids are pushed back down into the reservoir.

This avoids the need for full pipeline flushing.

Saves significant cost and offshore time, but may leave wax in the line posing environmental concerns.

That’s where our analysis comes in.

We needed to answer a critical question:

If we leave wax in the pipeline, how much will be there and will it pose an environmental or regulatory risk?

Our wax modeling has allowed us to forecast wax volumes, locations and growth rates with some clear results. These show that while wax is expected to deposit it is expected that the deposits are small (<2mm for the majority of the pipeline) and further are not expected to degrade or dissolve once production has ceased.

Under UK and OSPAR guidance, pipelines can be left in situ if residual materials pose no long-term environmental harm. Our analysis builds a strong, evidence-based case for that outcome.

We’re not on track to need an expensive, high‑risk cleaning operation. If the trend holds, the wax can be left in situ with minimal environmental impact, backed by a clear, evidence‑based case for regulators.

It also means we can focus decom planning on the things that will matter most: safe isolation, efficient removal, and minimising offshore time, instead of chasing a problem that isn’t going to materialise.

Lessons for the Future

Late‑life flow assurance isn’t just about keeping the wells flowing. It’s about understanding the system’s final years so you can make the right calls at the right time.

In our case, the hybrid monitoring approach:

Helps avoid unnecessary intervention costs.

Provides confidence in decom planning.

Shows how physics and data science can work together to solve practical, end‑of‑life challenges.

Closing thought

Decommissioning isn’t just dismantling steel. It’s telling the story of an asset’s last years and making sure that story ends well. Right now, the data says the wax layer will stay small; the pipeline will be ready to rest easy when the time comes.