Fluid Sampling During Production Operations

Cool Runnings: The Key to Smooth Operations

At Pontem, we are getting excited for the upcoming Winter Olympic Games, hence the catchy subtitle to talk about creating a smooth sampling and analysis program.

At its core, a good analytical program will provide enough leading and lagging indicators to know if a system is operating efficiently and when it is going off track. The trick, of course, is for the data to be useful and accurate, and while it sounds easy enough, the truth is collecting and running samples must be done “by the books” to avoid contamination or erroneous results. Here, our post explores some best practices to ensure your sampling and analysis program hits the bullseye.

All manned oil and gas facilities have a requirement to routinely sample and analyze the oil, gas and water to ensure that specifications are met to allow the hydrocarbon products to be exported for sale and the water to be discharged overboard. Failure to meet these specifications can result in fines, devalued product, or possibly outright rejection of the hydrocarbon product from the receiving company. Additionally, internal quality targets are often used to maintain asset integrity (i.e. corrosion and fouling) and/or maximize production rates. Failure to routinely sample and analyze the production fluids can significantly impact oil and gas production, hitting the bottom line of the operation.

In addition to the above, there will be process upsets that require numerous samples to be taken for analysis and troubleshooting to return the system to baseline. This can be a very important part of the sampling and analysis process because getting it right may mean the difference between producing and not producing hydrocarbons. Taking on deferred production due to unplanned shutdowns is definitely not “Cool Runnings”. See what we did there?! 😊

The ideal scenario is one in which samples are collected, analyzed, and results are in hand in a matter of minutes to hours. This requires the ability to do the majority of the analyses required on-site. To do this effectively means you need a lab. Sometimes it can be a bit of a squeeze to fit a decent lab onto offshore facilities but not quite as bad as this:

Correspondingly, the size of the lab limits what you can do and the equipment you can fit into the lab, but you still have a wide range of analyses to perform. Large footprint analyzers, rare or difficult to source solvents or disposables, and highly specialized training are all things that will limit the applicability offshore. We will go into exactly what type of analyses are needed later in this post.

So, with this limitation, it is unlikely that there will be much state-of-the-art equipment and sometimes you do feel like you are performing “bucket chemistry.”

The good news is that with the development in portable chemical analytical equipment there is still a lot that can be done and to a reasonable accuracy.

Taking that into account we will now go into a bit more detail on what analysis you need to do for oil, gas and water streams.

Sampling and Analysis Requirements

This process should be started during the design phase where the sample locations are initially identified. This process needs to make sure of the following:

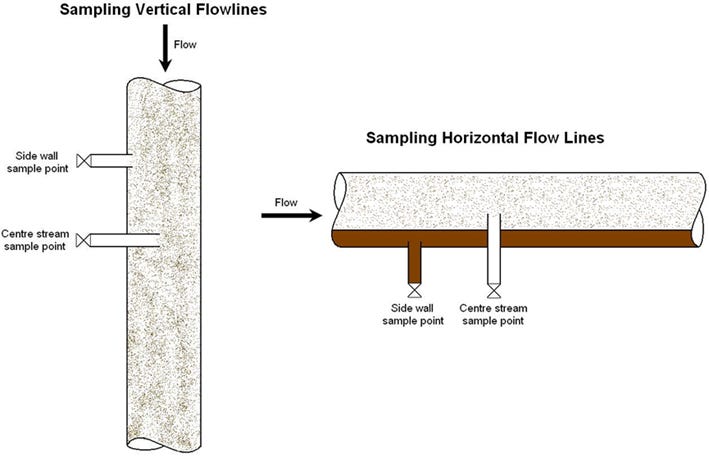

The sample point location and orientation is set correctly in the pipe or vessel. It is critical to understand what type of sample is being pulled at the sample point location so it can be spatially placed correctly. This includes understanding of the flow regime and/or how the vessel is configured. Nothing worse than getting water when you wanted oil! This includes placing the sample point at the 12 o’clock vs 6 o’clock position. Or placing the sample point near the oil outlet or water outlet for a vessel.

The sample point is accessible. In many instances, sample points have been located where they can’t be reached or that they are in such a small space you can’t get a sample bottle to fit underneath them.

Is the sample point in a horizontal or vertical pipe? This will make a difference on what type of sample you get as gravity will play a part in what type of flow regime you will have, which in turn will affect the phase that you will sample depending on where the sample point is located.

Acceptable and Not acceptable Oily Water sampling points

The pictures below also give examples of where to locate sample points in vertical and horizontal pipes

Safety First

Taking oil and gas samples can be a hazardous process and needs to be a managed accordingly. With sometimes having to break into high pressure and temperature systems. This may result in the sampling process requiring a work permit / risk assessment or as a minimum be supervised by an Operator. Things to look out for are:

Venting of hydrocarbons

This may cause small volumes of gas to be released, so this gas needs to be vented safely.Adequate training for the person taking the sample

The person taking the samples must know the HSE risks and follow properly established protocol to remove or minimize risks to a manageable level.Sample point integrity

Sample points should have double valve isolation and bleed valve assembly. i.e. double block and bleed with ideally a pressure gauge.Personal Safety Requirements

This involves the use of safety glasses/goggles/face shield, hard hat, appropriate gloves, safety shoes, clothing and breathing apparatus if gas samples with high levels of H2S are to be sampled.Impact of Static Electricity

Static electricity is a risk during sampling. Appropriate earthing procedures should be carried out. Refer to ASTM D4865-09 Standard Guide for Generation and Dissipation of Static Electricity in Petroleum Fuel Systems for details.Correct Sample Labelling and Sample Containers

For transportation it is important to make sure any sample taken is labelled correctly and is in the right size and type of container for the transportation method used. Proper labelling in the US, for example, includes DOT hazard diamonds with symbols and numbers, alongside GHS pictograms, signal words, and statements.Radioactivity of the Sample

For most liquid and gas samples this is not an issue due to the low levels of radioactivity present but if a solid sample has been taken, it is important to understand whether the solid contains NORM (Naturally Occurring Radioactive material).

As well as taking samples safely, you also need to take them correctly. There are good and bad ways to take a sample. Ideally you want to make sure:

The sample bottle is compatible with the sample to be taken. E.g. oil samples should be taken in lined metal cans or glass bottles and not plastic containers as the oil can react with the plastic container depending on the type of plastic used. (We’re looking at all you milk carton users!!).

The sample bottle is clean and uncontaminated.

The sample line from the sample point to the sample container is adequately flushed to an appropriate drain or waste container beforehand to ensure a homogenous sample is obtained.

I once went offshore to survey several unmanned and manned platforms in the North Sea. The operator had reported some stubbornly high OIW figures on a couple of platforms. On one of the manned platforms, I went out on the plant with the operator, who normally took the water samples for OIW analysis, and got him to take a sample as he normally would. Straight away he took the clean sample bottle, rinsed it out with the first water that came out of the sample point and then disposed of that water. Once that was done, he started taking the actual sample to be analyzed.

I immediately realized why the OIW levels were higher than they should be. This was due to the operator washing the clean sample bottle with the sample line flush. This water wash step left a film of oil on the inside of the bottle even though it was emptied out prior to taking the sample. The analyzed water sample produced an OIW value that was a combination of the fluids from the flush and the actual water sampled. It turned out this increased the OIW value by 20-30%. The corrective action was to flush the line into a suitable disposal bucket or waste stream and then collect the water sample with the clean, previously unused collection bottle. The OIW values immediately returned within required specifications.

So what samples should you take

Once you know where and how the sample will be taken, it is important to understand why you want to take the sample in the first place. Most samples are taken to verify that the oil, gas, and water are within specifications. It is important to note this often requires more than one analysis per fluid, as several parameters need to be monitored. The following sections give an indication of what samples should be taken and what analysis to perform.

Oil Samples

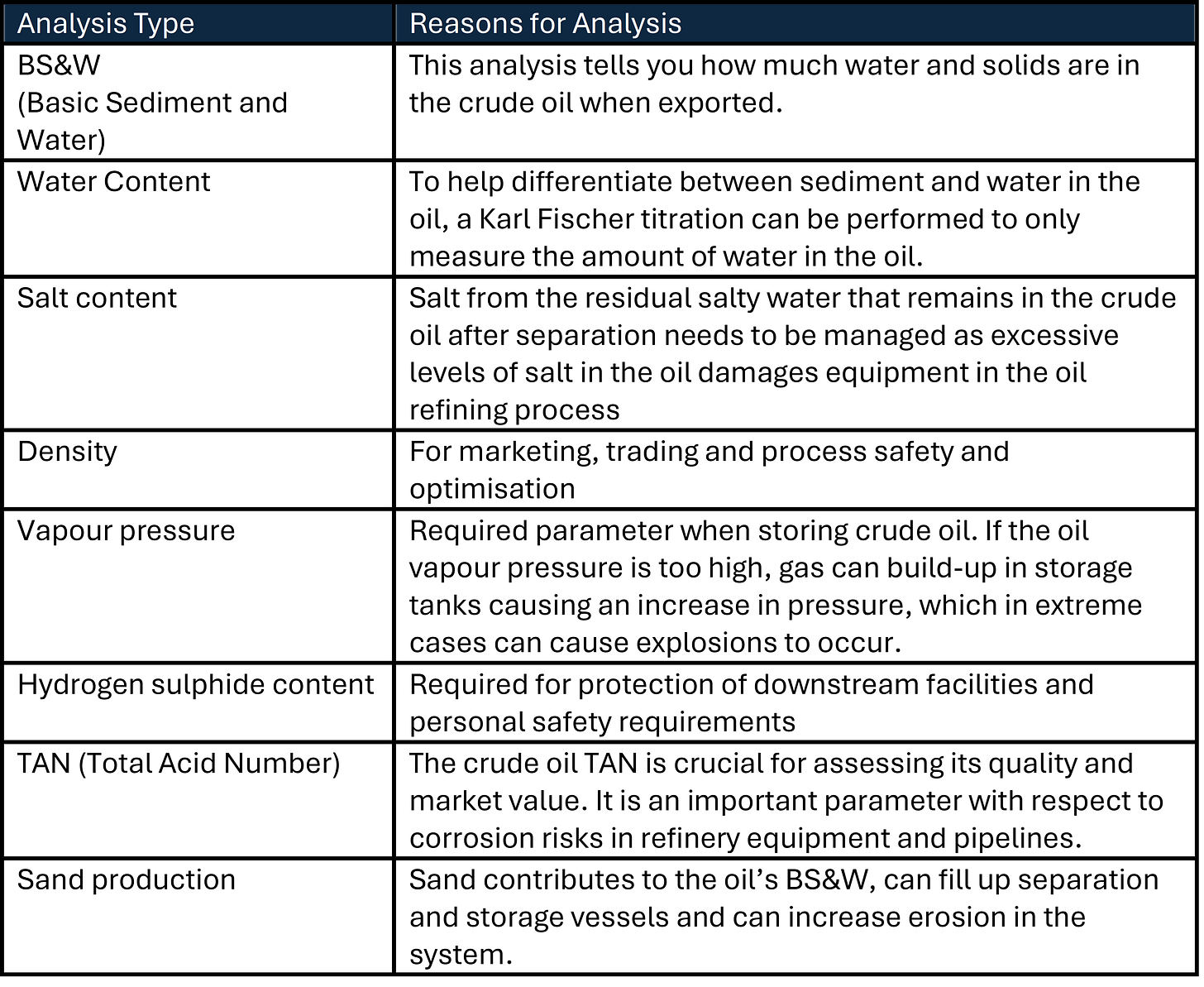

The main variables requiring monitoring in crude oil producing operations are:

With respect to sand, measuring the amount of sand being produced is a lot more difficult than you would think. It needs a specialized sand sampling system. See the picture below:

Samples of sand need to be taken from sand removal systems to measure the amount of entrained oil before the sand is discharged overboard. There is a risk for oil sheens if oil levels on the discharged sand are too high similar to the one in the picture below.

Gas Samples

As with oil, there is a lot of effort put into monitoring the quality of the gas to make sure it is suitable for export. To get the right gas specification there may be various gas treatment systems being used such as:

Gas dehydration

Acid gas removal (i.e. CO2 and H2S)

Condensate dew-pointing

Mercury removal

To ensure these gas processes are working as effectively as they should be, gas samples need to be taken and analyzed at regular intervals. This may involve the use of online sampling and analysis systems.

Even with online systems being in place, there is a need for manual sampling and analyses to be performed offline to validate the performance of the online systems.

Operations that are relatively simple and/or where plant upsets are infrequent or low impact may require only periodic sampling and analysis of the gas streams to be performed. For example, this may mean only a simple chromatographic analysis to C8 and/or a dew point measurement is sufficient.

Where more in-depth analysis is required, gas samples may be further tested for the following gas properties:

Calorific value

Relative density

Hydrocarbon and water dew points

Mercury

Concentrations of sulphur compounds

BTEX

Inerts

As well as the above gas properties periodic monitoring of the glycol used for gas dehydration or hydrate inhibition may also be required.

Finally, some of the above gas properties can be used for monitoring the gas process performance or for quality control of the gas being exported. These properties are used as key features in the quality specifications attached to gas sales agreements, so any analysis needs a high degree of accuracy.

Water Samples

Although water is not a revenue generator, there are multiple system health checks dependent on proper and routine water analyses. These are:

It is worth noting that when it comes to water, the environmental analysis requirements are based on where the water is being discharged. If it is offshore (>12 miles from shore), well away from the coast line, then the analysis requirements are much less onerous compared to water discharged onshore, in a river/lake or near-shore (<12 miles from shore). This is because the impact the discharged water will have on humans and the indigenous flora and fauna is likely to be negligible for offshore scenarios thus requiring less tests. However, when the discharge is onshore, near-shore and in rivers or lakes then you will likely need to analyze the composition of the water far more closely. You can see these differences in the lists below .

Environmental requirements - offshore

Total Oil and Grease (TOG) - aka Oil-in-Water (OIW)

Depending on the global location that can just be measuring the dispersed (insoluble) oil in the water or the total hydrocarbon content of the water that includes both the dispersed and water-soluble hydrocarbonsMonitoring “grey water” / sewage discharges offshore

Environmental requirements – onshore / near-shore

Total Oil and Grease (TOG) - aka Oil-in-Water (OIW)

Total Suspended Solids (TSS)

Total Dissolved Solids (TDS)

Total Organic Carbon (TOC) and/or Chemical Oxygen Demand (COD)

Total Nitrogen

Total Phosphorous

Escherichia (MPN/100ml)

Faecal enterococci (MPN/100ml)

pH

True colour (Wavelength/ Maximum spectral absorption coefficient)

Acute toxicity (UT)

It is worth noting that the above list of tests are some of the most common tests that need to get performed. Depending on where you are in the world will determine how many of them you will need to do.

Process Performance requirements

Total Oil and Grease (TOG) - aka Oil-in-Water (OIW)

TSS

Bacteria ATP

Bacteria qPCR

CI Residuals

SI Residuals

Ca/Mg ratio Mn2+ and Fe2+ conc.

pH

Water Composition

The above analyses are the requirements for the produced water when managing things like corrosion, scaling and water quality.

If you are also using seawater injection into the reservoir to help enhance production, then there is a whole new set of analyses that need to be performed to ensure the seawater is the right quality for injection. Specifically, the seawater injection stream should be tested for:

Dissolved Oxygen

Free and Total Chlorine

TSS

Water Quality

SO42- (this is particularly important if sulfates are a concern and/or a Sulfate Reducing Unit (SRU) is in place)

These are the sampling and analysis requirements for the main production and injection streams but there are a number of other parts of the process that need to be sampled on a frequent basis. These include but are not limited to:

Off Spec Oil Tanks

Fuel Gas

Diesel Storage Tanks

Closed Loop Cooling Medium

Closed Loop Heating Medium

Lean TEG

Rich TEG

Fresh Water Generators

Slop Oil Tanks

Slops and Bilge Water

Subsea Chemicals

Subsea Hydraulic Control Fluid

Sewage Treatment Package

As you can see most oil and gas facilities need to take and analyze large numbers of samples just on a routine basis. This increases further when something unexpectedly goes wrong and may even start to include solid samples but how to deal with solid samples is probably another Substack post in itself.

Sample Data Management – It’s our Thing!!

As we just described, there are a multitude of oil, gas and water samples that need to be taken on a routine daily, weekly or monthly basis. As well as the manual samples there are online analyzers that you can add to the system that will analyze in real time things such as

BS&W

OIW

Water content of gas

O2 content of injected seawater

Corrosion

Particle counts

Even when you have online analyzers, manual samples are still required to ensure the analyzers remain calibrated.

When you have this instrumentation and its combined with the manual sampling and analysis data this provides integrated data feedback with the data generated directly via the analyzers and instrumentation, which is then used to maximize the efficiency of the overall system by managing the data generated.

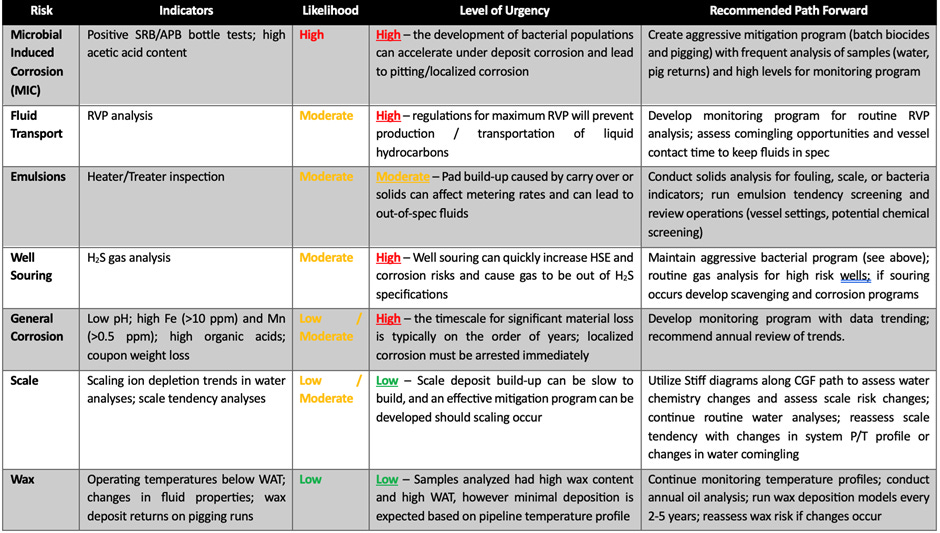

Doing something useful with the data to improve processes is really the point to all the hard work of sampling and analyzing properly. The following two examples highlight the difference between collecting samples in a single point in time to develop a risk analysis compared to a monitoring system that delivers trends and actionable insights over time for an entire system. The table below shows 7 risks identified from sampling a Permian system. Framing those risks in a likelihood and consequence (or level of urgency) matrix provides a framework for creating an effective mitigation or risk removal program. Corrosion and souring risks are identified and a path forward is recommended, however it will be up to the field to maintain these programs and to set threshold levels for a monitoring program.

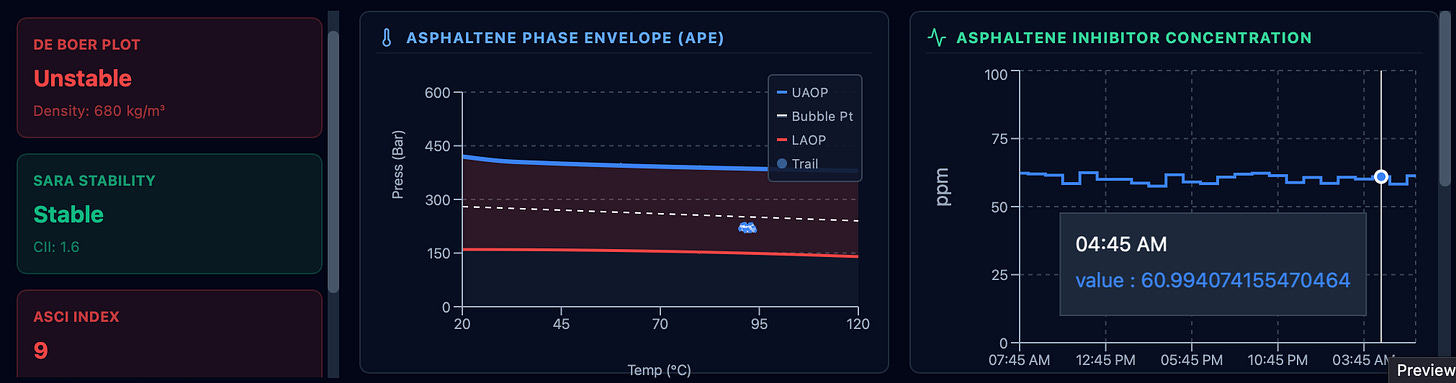

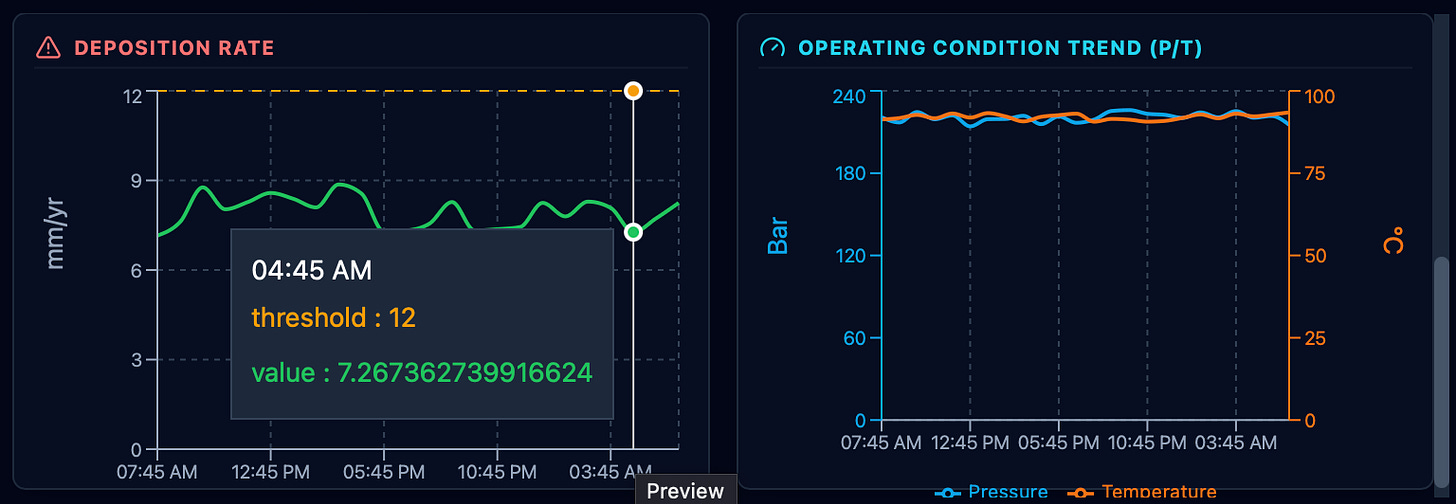

In contrast, online dashboards that trend systems continuously are able to identify risks as fluid properties change. In the example below, 7 wells are monitored on a continuous basis with plots of P/T/chemical injection rates highlighted on a dashboard, along with thermodynamic risks for asphaltene instability and a simulated deposition rate. The system provides real-time feedback, and in the case of W-BF-2 well the dashboard is recommending a 25ppm increase in AI to reduce the risk from medium to low and examine BH pressure data to recalibrate the system.

Yeah, But I Don’t Have Time For All That…

We get it: sampling, analyzing, and processing all that data can feel daunting and cumbersome. And it can often appear that a system is running smoothy. Going through the motions without a real understanding of what is truly happening will eventually bite you. The US bobsled team just found this out at the World Cup Bobsled event while tuning up for the Winter Games. Good timing for our post…bad timing for our Olympic hopefuls!

Without those leading and lagging indicators that will crop up in routine sample analyses, bigger problems will cause massive issues, making it more difficult and more expensive to right the ship.

The good news is you don’t have to go it alone. Partnering with Pontem Analytics is a sure fire way to set up and establish a robust testing regime that includes all the metrics you will need without the ones you don’t. Reach out and start the conversation. We’re happy to help.

Thanks for reading Data and Discipline! Subscribe for free to receive new posts from Pontem Analytics.