Data Without Borders

Refining our Downstream Business Model

Endless Summer

What did you do this summer? Go anywhere fun?! Pontem made several splashes across the globe, to name a few: participating in a joint project for Methane Hydrate production (Japan), technology transfer collaborations (Mexico), contributing to the Prinos CCS project (Greece), supporting H2ALL’s efforts to bring clean water to rural communities (Uganda), chairing multiphase flow conferences (Portugal) and collaborating with various universities (Mediterranean). We also found time to get down…stream, that is. Why does this make sense for us and how do we differentiate ourselves in this space?

Loadin’ up and living right; Fast cars on a summer night

If we’re being honest, we have a history of going about our business a little unconventionally. Fundamentally, we believe the way we approach problems is translatable to multiple industries, and especially across the Energy sector. To say we solve problems does not really capture the value-add to our clients and may suggest we simply put a number on the right side of “=”. We believe our value-add is tell our clients what that answer means for them! The interesting part is when the conversation leads to “What if…” discussions and soon there is a matrix of solutions that provides options and an intelligent basis from which our clients can act.

Because we think this approach will resonate in downstream energy, we are confident we speak the same language. (Did you know: Our co-founder actually began his Energy career working FCC units across the refining sector AND our first project at Pontem was for hydrate monitoring in the downstream market) Not to put too fine a point on it, our data analytics approach is based on our collective experience as oilfield engineers and chemists and really honing in on the domain knowledge to better leverage the data. I mean, seriously, tell me if you’ve heard this one before:

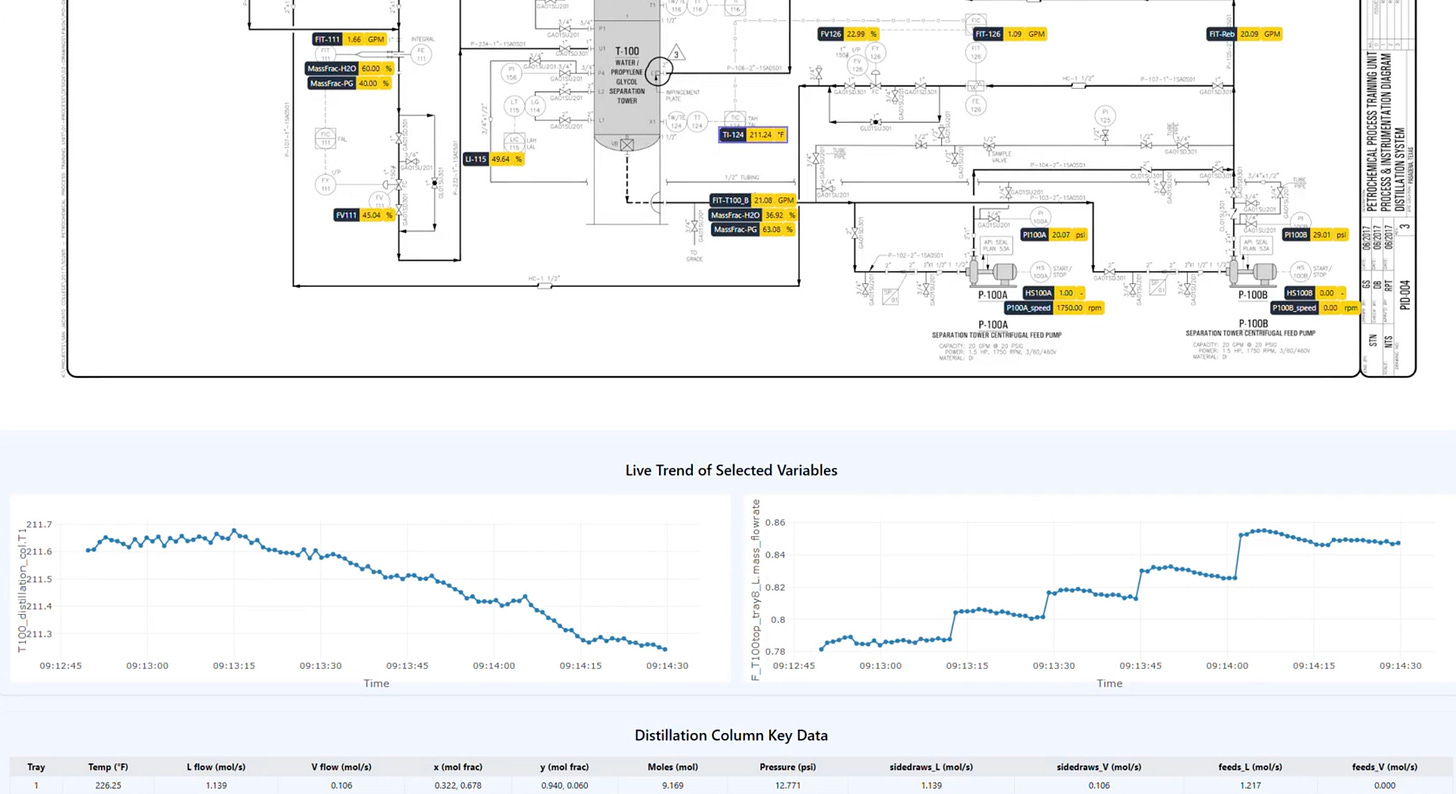

Construct a Digital Twin

Look for plant inefficiencies and available margins

Interact with a real-time optimizer OR go next level and utilize an APC thinly disguised as a new product

Use the new product as a lens to report highest profitability under similar input conditions

In the shop window, it may look good, but soon you realize all these approaches are pretty similar.

The Balkan Peninsula

We are keenly aware of projects more in our wheelhouse in the Balkans, particularly in the Black Sea. OMV Petrom and Romgaz are developing Neptun Deep in the Romanian space, while the Bulgarian government has signed two exploration agreements: with Shell to explore 4,000 square meters in the Block 1-26 Khan Tervel field, and with OMV Petrom and NewMed Energy in another field off the Black Sea coast. We are still being opportunistic in the upstream arena, but we also think we can make an impact in Energy in this region in the Downstream arena.

Breeze is warm and music’s right; This endless summer

We were recently invited to a refinery in Europe to discuss their journey through digital transformation, share our capabilities, and explore our approach to data. Compared to more traditional upstream - where error bands may be inherently larger - we are now focused more on the ‘aggregated micro’ to realize those gains. Instead of +/- 10% over km of pipe, we are now +/- 10 psi in the reactor.

We are agnostic in our technology of choice, and have implemented everything from physics informed machine learning platforms to more nimble, lightweight data-driven models and target analytics, which offers multiple options in areas like mechanical availability, predictive maintenance, and smart manufacturing.

The Next Frontier For Data In Refineries

One topic that came up during our visit was process optimization. We were able to share our experiences developing models and tools that require handling multiple variable interactions and operating limits. Enhanced APC solutions are useful, despite my earlier dig, and can provide elegant solutions for these complex processes.

Optimizing Predictive Maintenance

Process upsets, equipment maintenance and failure, and efficiency losses can lead to unplanned downtimes, safety risks, and financial losses for a refinery. Developing tools to anticipate failures before they occur is one avenue to explore that can directly minimize downtime, save on costs, and improve uptime metrics. We excel in exploring these “what if…” scenarios to provide actionable and meaningful data. To the naked eye, it may not seem as if there is an obvious solution, however this is where we thrive. We are excited to continue our conversations with our new friends!

Closing Thoughts

Machine Learning is a big, generic term and a lot of companies are capable of delivering AI products and refineries have been implementing with success. While I trivialized a few concepts in jest earlier, a few real ML examples reported by refineries include significant benefits:

Shell reported using ML digital twins to optimize steam cracking, resulting in $25MM/yr savings

BP has implemented ML strategies in hydrocracking and have reported an increase in diesel yields by 6% when utilized

ExxonMobil has incorporated predictive analytics to reduce some equipment downtime by 30%

We believe to make the next leap in data analytics companies must ultimately understand the environment they’re operating in and understand what the data saying and how can these products ultimately help the client? Our team has multi-decades worth of experience throughout the Energy Supply Chain based as operators, service providers, engineers, and consultancies. Because we came from the same space as our clients, we understand how to make tools deliver results that will make real impacts on their processes.

We look forward to visiting your facilities and collaborating on your data analytics products!