Arigatō, Japan

KHIs, Sand Control and Snake Sake

Last month, Pontem Analytics made its first trip to Japan, joining our Australian laboratory partners at Oilfield Technologies. The visit followed on from a successful collaboration between Pontem and Oilfield Technologies for the Japan Methane Hydrates Operating Company (JMH) in late 2024 and early 2025. In this article, we share insights from the trip and what Pontem’s Pete Conrad and Conor Sherrard learned from Japan’s forward-thinking approach to methane hydrate gas extraction.

Find out more about methane hydrate gas extraction here!

JOGMEC / JMH

Our first day began with a visit to the JOGMEC offices for discussions on the optimisation of kinetic hydrate inhibitor (KHI) technology for methane hydrate extraction. Unlike conventional gas production, methane hydrate deposits present unique challenges—most notably, the absence of a free oil or condensate phase and the presence of large volumes of water (approximately 6 moles of water for every mole of methane…or ~859 bbl water for every MMscf of methane!).

To ensure KHIs perform optimally under these conditions, Pontem Analytics, Oilfield Technologies, the University of Western Australia (UWA), and JOGMEC are working together to ensure the best formulation is selected and the best application design is installed to minimise hydrate reformation risk during production and maximise uptime.

This collaboration brings together a team with distinct but complementary skill sets:

Pontem Analytics' expertise in formulating and deploying KHI products, through Dr Pete Conrad and Stephen Hamilton.

Oilfield Technologies' extensive experience in KHI performance testing.

UWA’s deep knowledge of hydrate science, molecular chemistry and laboratory-scale testing.

JOGMEC/JMH’s operational insight into the practical challenges of methane hydrate gas extraction.

The day’s productive and engaging discussions wrapped up with a well-earned dinner in Tokyo.

JMH

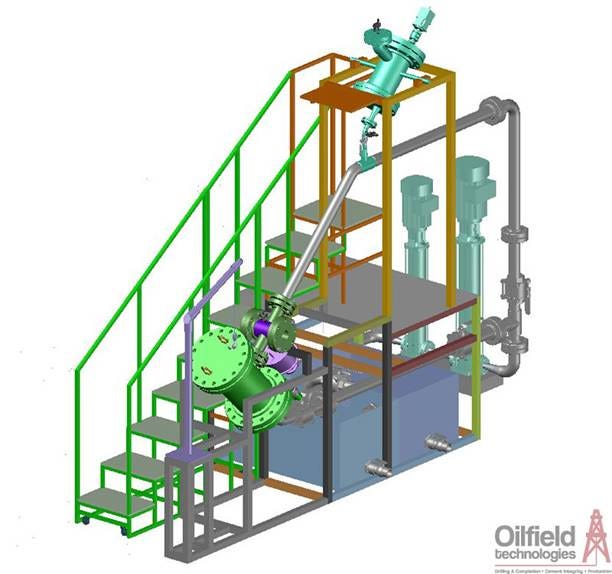

Our second day in Japan kicked off with a visit to JMH’s offices to discuss the sand control challenges of producing gas from methane hydrate deposits. Sand trapped within the deposit is loose and unconsolidated, presenting challenges from a subsurface (sand packing / collapsing) and production (erosion / equipment damage) perspective. Thankfully, Oilfield Technologies have the answer with a state of the art solids production test rig with the capabilities to test all forms of downhole sand control under downhole conditions. Producing real test data of the downhole sand control options, alongside Pontem’s ability to model erosion in complex pipework, allows for confidence in the final downhole sand control and well design.

Following on from these discussions, we recapped the flow assurance study performed earlier in the year and discussed the potential for more innovation and analysis going forward to ensure the next production test is successful.

Pete and I capped off the day with a well earned Snake sake. No, that is not a brand of sake, that is sake with an actual snake in it! We both felt a bit off the next morning….

INPEX

Our next day included a visit with friends at INPEX, Japan’s largest petroleum and exploration company. INPEX has plenty of experience handling traditional hydrates. Discovered in the Browse basin in 2000, INPEX developed the Ichthys with partners (including TotalEnergies and Osaka Gas), which manages hydrates using MEG. Designed for 100,000 bbl/d condensate and 9.3 MMt/y gas produced through a gas export line 890 km pipeline to an LNG facility in Darwin, Australia. (Interesting side note: Pete was part of an RFQ from INPEX in 2009 to examine whether LDHI may be a suitable option for hydrate management). First production began in 2018 and in just over a year later the 100th LNG cargo was shipped, which is quite impressive!

As part of INPEX’s commitment to providing sustainable energy to the Asia-Oceanic Region, they are partners in a number of other regional fields, including Santos-operated Coniston Van Gough and Woodside-operated Ravensworth fields. Additionally, INPEX is leading efforts to decarbonize many of their operations, including the Ichthys LNG project. With key infrastructure upgrades in the works, INPEX is planning to be CCS-ready utilizing technology to capture CO2 during liquified gas production, where they will compress, transport, and store in permanent, underground storage reservoirs.

Nippon Shokubai

Our final visit in Japan was with Nippon Shokubai, a specialist chemical company, whose products span a wide range of applications. Their company name literally translates to Japan Catalyst, and they began their impressive history perfecting the synthesis and production of phthalic anhydride, an important raw material used in coatings. Without being aware, many people use their technology today: the most famous example is the incredibly absorbent material used in diapers! Equally important, Nippon Shokubai is well-established in the Energy Sector. A few examples include:

Electrolyte for Lithium-Ion Batteries: IONEL (LIFSI) (shameless Pontem plug for Li-extraction roll-up post we did: https://dataanddiscipline.substack.com/p/lay-the-smack-down)

Scale Inhibitors for drilling

Additives for drilling mud

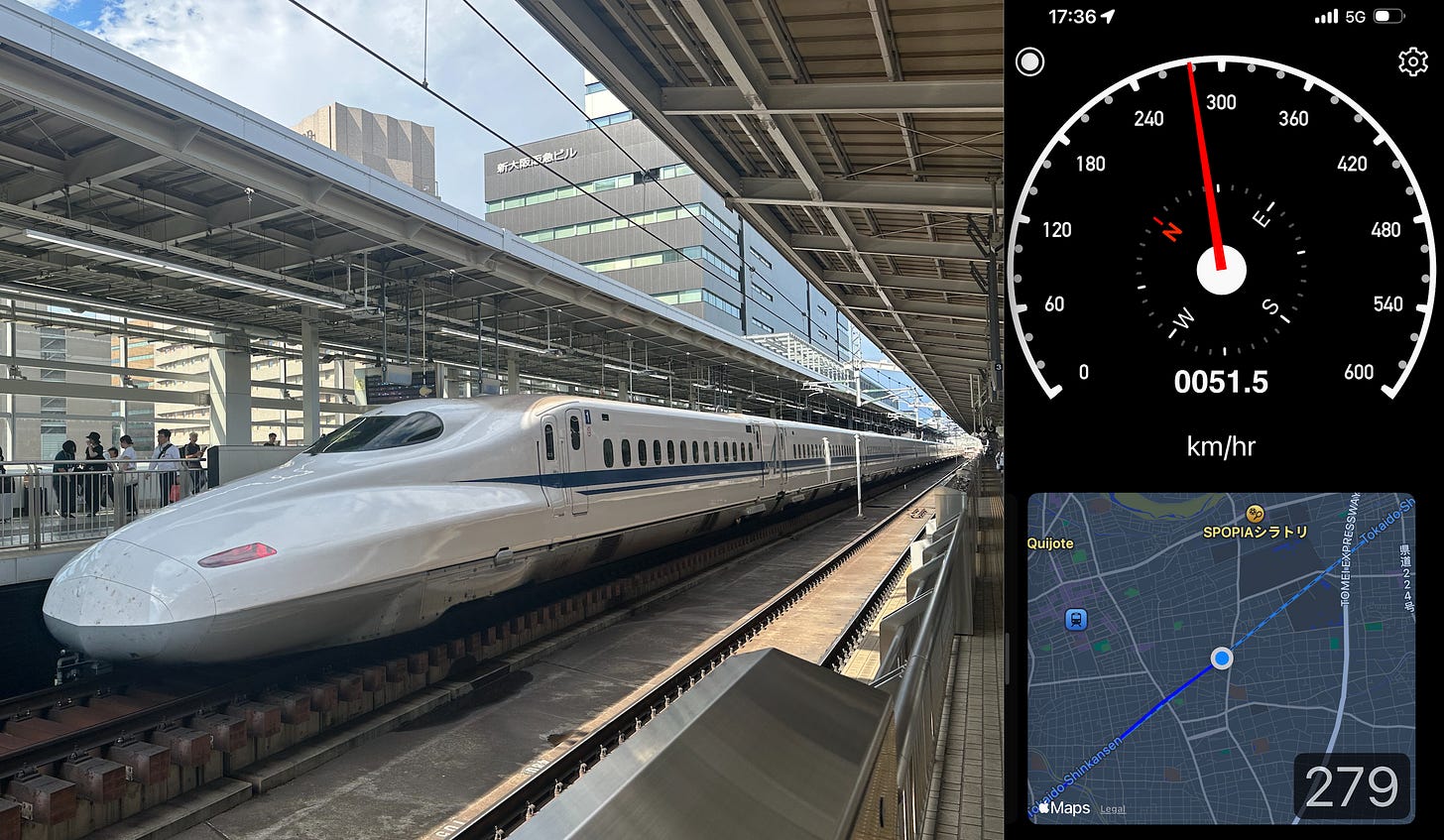

We needed to travel from Tokyo to Osaka, about 500 km (310 miles) away. This isn’t a problem thanks to the Tokaido Shinkansen line: we made the jump in just under 2-1/2 hours! Team McLaren might laugh at my speedometer app image, but it’s the fastest I’ve travelled on land.

Nippon Shokubai took the time to show us around their laboratory and research facilities to highlight their world class capabilities in chemical development. It was a great opportunity to share experience in chemical manufacturing and performance testing, and the potential for Nippon Shokubai to expand their chemical portfolio further into the oil and gas space.

Pontem would like to thank JMH, JOGMEC, INPEX, and Nippon Shokubai for their hospitality whilst in Japan. Furthermore, a massive thank you to Katsuei-san for looking after us and making sure we only ate the best Japanese cuisine!