A History of Reservoir 3D Printing

Bringing Subsurface to the Surface

How Everything Started

The story begins with the moment captured in the photo below: it’s 2019, and I’m being awarded for my academic achievements by Vance Greene, then a regional manager at Noble Energy, during the UNIC award ceremony.

At the time, it felt like a straightforward recognition of hard work, but looking back over the last six years, it’s clear that this award was far more than a monetary prize—it was my "Golden Ticket." It led me to cross paths with Tommy (and the whole Pontem Team!), where we continue to work together now. I can’t express just how grateful I am to Vance for the impact he’s had on my career—so, if you’re reading this, Vance, there’s a dinner waiting for you in Cyprus!

After the ceremony, Vance and I discussed how Noble Energy (now Chevron) might support educational programs as part of their Corporate Social Responsibility (CSR) projects. I remember reflecting on my own experience of late nights building the reservoir model for my thesis. It struck me how valuable it could be for the next generation to truly understand where we produce oil and gas today—not just through pictures, but by experiencing something tangible, something "real." I envisioned using innovative 3D printing technology to bring these concepts to life. I was certain that the idea had potential, but I lacked the equipment and technical know-how in 3D printing.

Just a week later, I received an email from Christiana Pieri, then at Noble Energy, inviting me to discuss my ideas further—an unexpected step that would turn out to be pivotal. Back then, we couldn’t move forward with the project, as we were both caught up in our own work, and I soon left to pursue my career at AFS in London. However, we kept in touch over the years. When I eventually returned to Cyprus with Pontem Analytics, Christiana reached out again, this time introducing me to a company that specialized in 3D printing.

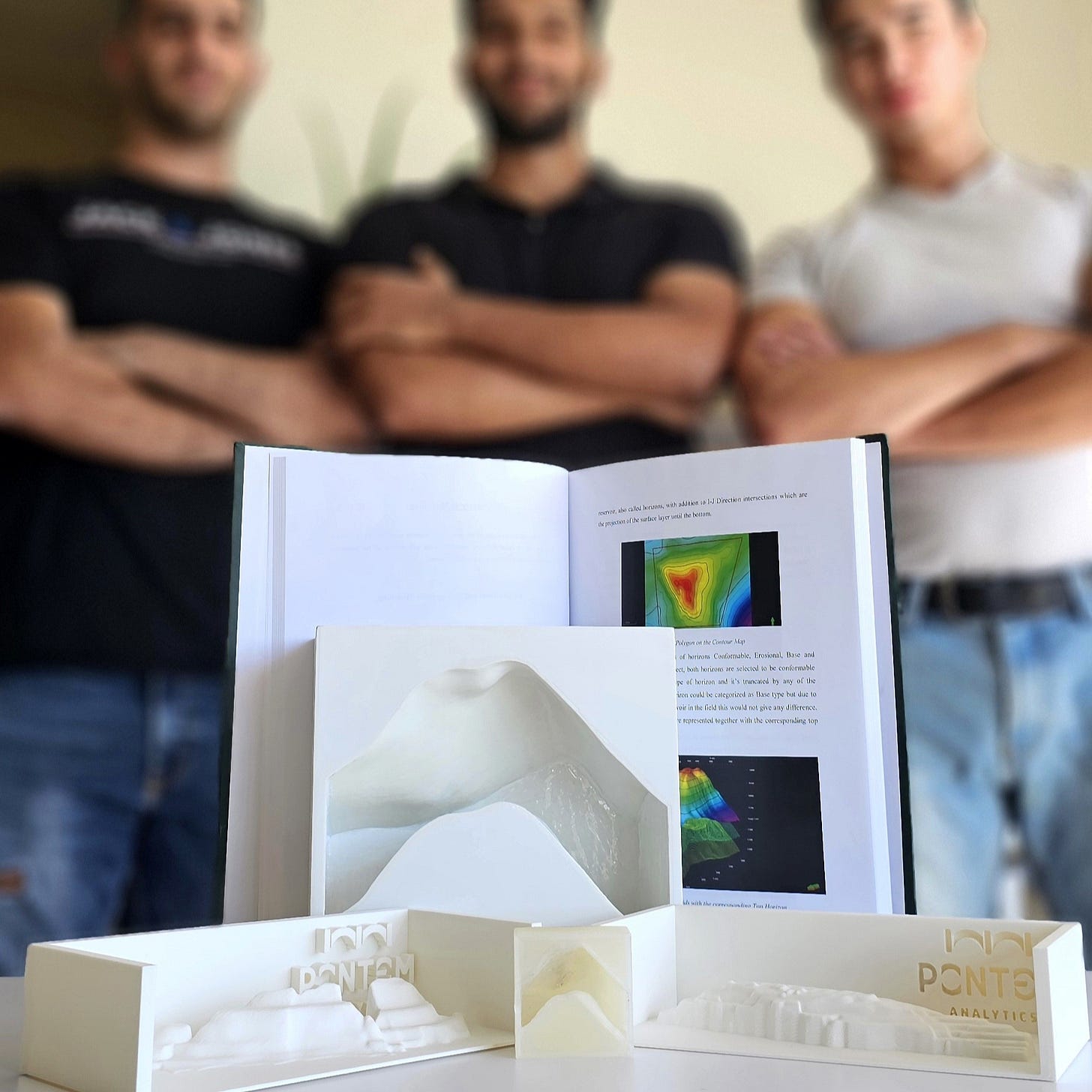

After discussing all the details and seeing the Cyprus Pontem team come together, we realized that we had the skills and resources to take on the project ourselves. While our approach might not have matched the polish of a professional 3D printing firm, we were able to achieve a very satisfactory outcome—one that brought our original vision to life.

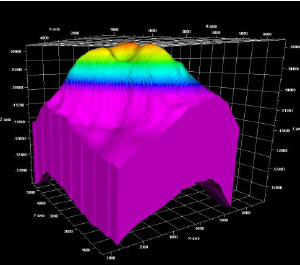

Petrel - Reservoir Model

Reservoir engineering quickly became one of my favourite subjects during my university days. For my thesis, we worked with real field data from a disclosed field in the North Sea. Our task as a team was to develop a Field Development Plan (FDP), assuming that the existing reservoir was located in Cyprus. It was a challenging but rewarding experience, and I’m sure that my teammates—Alex, Karim, and Chelsea—would be proud if they saw this post reflecting on that hard work.

The project involved processing an extensive range of data, including well logs, fluid properties, seismic surveys, sand formation details, and much more. Through this ocean of information, we constructed the final reservoir model using Petrel, a leading software for reservoir modeling.

The 3D models that emerged from this process were truly eye-catching, offering a unique perspective that can’t be found in textbooks.

It struck me that this kind of knowledge—understanding the structure and formation of an oil and gas reservoir—was something rarely taught, especially not in early education like high school. That’s when the idea came to me: why not bring these models to life through 3D printing and help younger generations visualize how an oil and gas "nest" really looks?

How a 3D-Printed Reservoir Model Could Benefit Students:

Visualizing Complex Geology: A 3D-printed model can transform abstract geological concepts into tangible objects, making it easier for students to grasp the structure of reservoirs and the layering of different rock formations.

Hands-On Learning: By holding a physical model, students can engage in hands-on learning, which is often more effective than just reading or listening. It allows them to physically explore the shapes and complexities of underground reservoirs, fostering a deeper understanding of how oil and gas are stored and extracted.

Bridging Theory and Practice: A 3D model serves as a bridge between classroom theory and real-world applications, helping students connect textbook knowledge to the practical aspects of reservoir engineering and energy production.

Interactive Teaching Tool: Teachers can use the 3D model as a dynamic teaching tool, guiding students through the layers and features of a reservoir while addressing questions in real-time. It’s a more interactive way to teach about natural resources and the energy sector.

A lot more!

Can we touch it? Finally, yes.

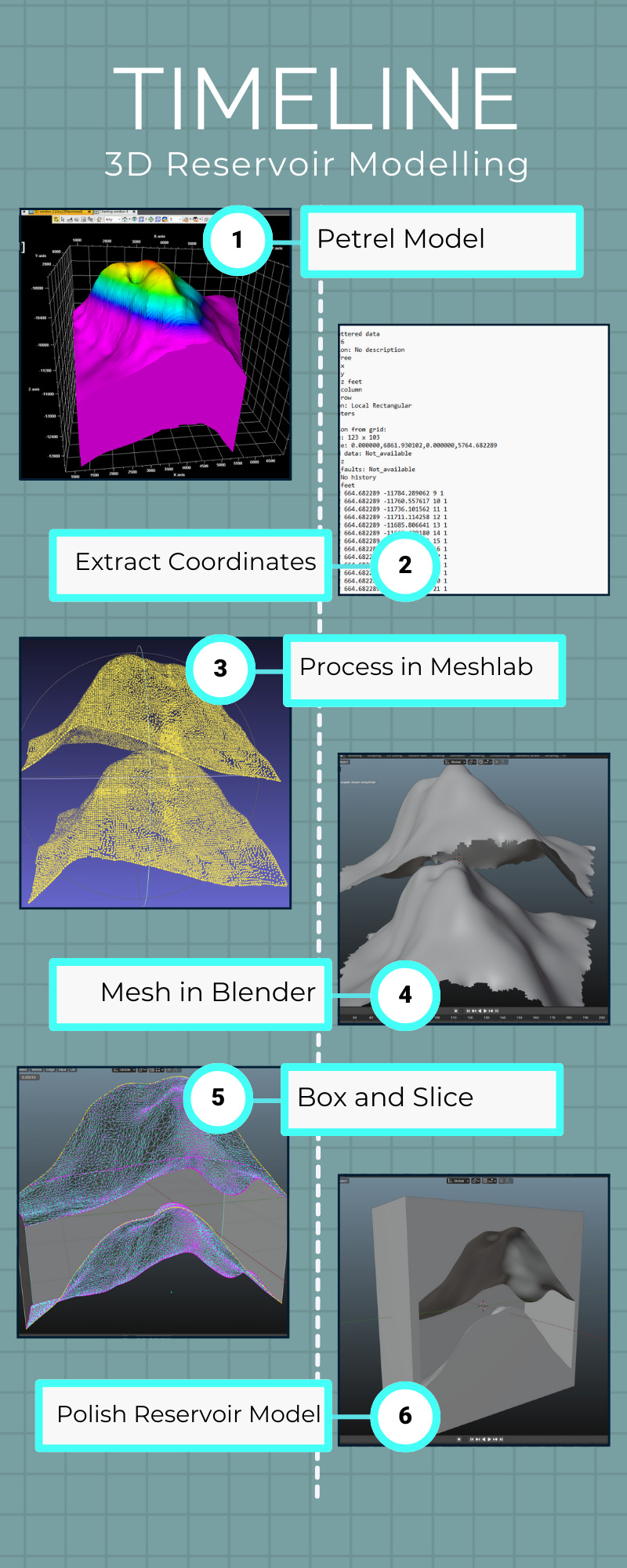

With all the coordinates extracted from Petrel and scaled down to create an object file, the final challenge was finding the right equipment to print the model. Building a 3D model using different software was no simple task, but thanks to Markos and his impressive design and programming skills, we managed to generate the model using a combination of 3-4 different software tools. Below, you’ll find a brief timeline of the steps we took to build the model—though it’s a simplified version of what was, in reality, a much more intricate process.

Initially, we were close to outsourcing the printing process. But then, by a stroke of luck, Dimitris, our MSc thesis student, mentioned that he had been participating in competitions for 3D printing. Intrigued, I immediately showed him what Markos had created, and Dimitris was confident he could handle the printing, given that all the necessary data was available.

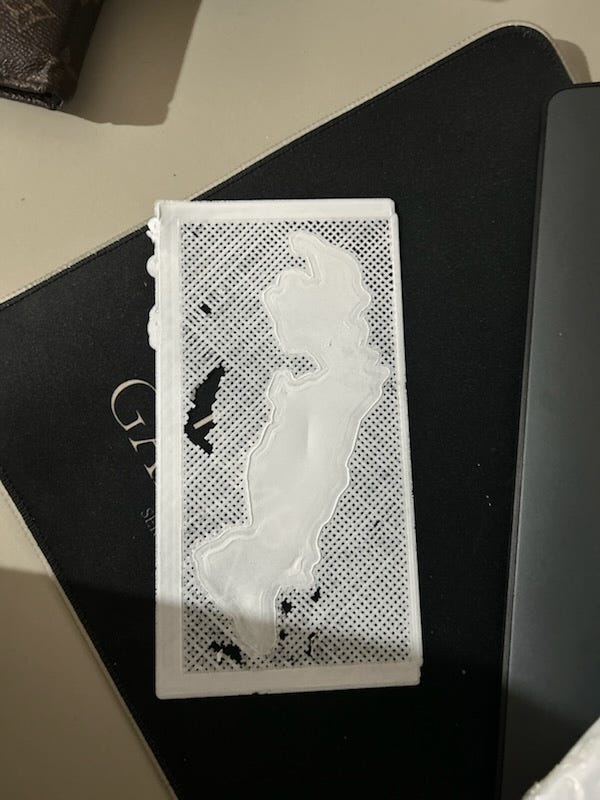

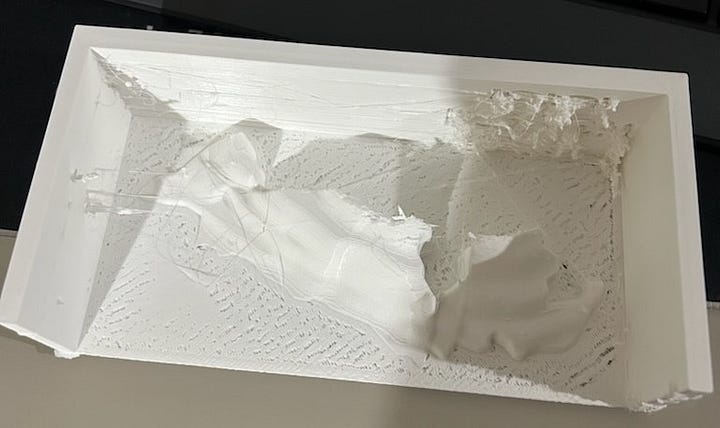

Dimitris's expertise in 3D printing, honed through his experience in various competitions, quickly became evident. His skill level was well beyond what we’d initially anticipated, and he managed to bring our vision to life in a way that impressed us all. I won’t lie—seeing the first print of the reservoir model was a moment of excitement. It looked exactly as we had imagined, capturing the intricate details of the subsurface formations.

All that remained was to add the finishing touches—like filling the model with representations of oil, water, and gas and sealing it. Of course, more ideas kept popping up, like adding miniature wells or hand pumps, but those are concepts for the future!

Next Step - Building Model from “Nothing”

As is often the case, the best ideas tend to emerge after a few glasses of whiskey. During Tommy's visit to our Cyprus office, we found ourselves brainstorming about what else we could do with this 3D printing concept. One major challenge was that reservoir data is typically confidential. We can’t use it for anything public, and often, the reservoir models themselves aren’t even shared with us since our focus is mainly on the reservoir's output.

But as we thought about the kind of data we might need to create similar models, we realized that the most accessible source might just be something as simple as publicly available images of reservoirs. While these images don't seem like much on the surface, they contain enough information for us to create an approximate top view of a reservoir using elevation heat maps (you can see an example below).

Sure, this approach only gives a rough idea of a reservoir's visual appearance—it doesn’t capture internal details like faults or layers, and the dimensions are far from precise. But after everything we’ve learned through this project, we know that if a 3D reservoir model is provided from Petrel, even just the basic coordinates, we can accurately scale it down and print a faithful representation.

Getting to a working 3D-printed model was far from straightforward. We faced plenty of trials and failed prints along the way—models that warped, crumbled, or just didn't resemble the reservoir we envisioned.

Dimitris and Markos spent countless hours, even entire days and nights, poring over the problems and troubleshooting every little detail. Dimitris, with his competition-honed expertise, meticulously added supports within the print to keep the reservoir structure in place during the printing process. After all that effort and determination, we finally achieved the ideal print—one that truly matched our expectations.

The potential applications are endless, depending on the client’s needs. Whether it’s a conversation starter for an office desk or a teaching tool for university classrooms, a scaled-down 3D model of a reservoir is more than just a cool piece of decor—it’s a physical representation of the complex underground worlds that fuel our energy needs. And who knows? If you dig a little deeper, there might be even more uses we haven’t yet uncovered.